Hot Products For All Applications

MP10

Multi-line text content element

HTML language content can be parsed after rich text content is bound to data

Classification:

Metal-Polymer Composite Bearings

Key words: Electrolyzed water equipment

- DESCRIPTION

-

Product introduction

MP10 is a type of metal-polymer composite of trilayer structure, designed for dry operation. Low carbon steel is used as its backing material. Under high temperature, a layer of bronze powder is firstly sintered onto the steel backing as inter-layer and subsequently the lining layer(mixture of PTFE and fillers) is sintered onto the bronze layer. The steel backing can provide powerful support, ensuring dimensional stability for the bearing. The porous bronze layer serves as carrier and retainer for the lining, providing function of heat dissipation. This scientific design of structure enables MP10 to have excellent tribological properties.

When a MP10 bearing operates, in the running-in period, a surge of coefficient of friction normally occurs within a short time and some of the polymer would be transferred to the mating surface,forming a solid lubricating film. Over the next normal operation period, the coefficient of friction can be at a very low level for a long time and the solid lubricating film can maintain there until the end of bearing service life.

During operation, stick-slip phenomenon is negligible due to the excellent lubricity of the polymer. It can be satisfactorily compatible with external materials. So that, MP10 can operate well even in dusty working condition. Also MP10 can be used in the most fluids which does not chemically attack the bearing material, such as water, lubricating oil, engine oil, turbine oil, hydraulic oil, solvent,refrigerants. As a matter of fact, under lubricated condition. It performs better with lower coefficient of friction, lower wear rate and can endure higher PV value.

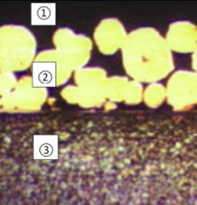

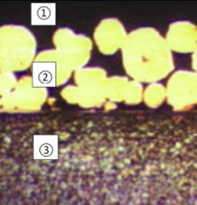

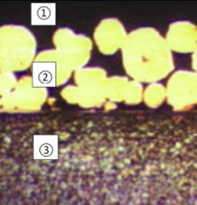

Material structure and composition

①lining layer ( mixture of PTFE and fillers),0.01-0.03mm thick.

②porous bronze sinter layer, 0.20-0.30mm thick.

③steel backing ,copper-plated or tin-plated.

PropertiesParameter Condition Value Max. load Static 250N/mm² Dynamic 140N/mm² Max.speed Dry 2.5m/s Oil 5m/s Max.PV (dry) Short time 3.6N/mm²*m/s Long time 1.8N/mm²*m/s Temperature range ℃~+280℃ Coefficient of friction 0.03-0.20 Thermal conductivity 42W(m*K)-1 Coefficient of linear thermal expansion 11*10-6*K-1 Product Features-Quiet operation.

-Capable of dry operation without lubrication.

-Suitable for linear, rotating and oscillating movements.

-Low friction and high wear resistance

-Excellent anti-corrosion and chemical resistance.

-Lead-free, compliant to RoHS specifications.

-Simple and compact structure, reducing size and weight, easy installment.

-Performance improves in lubricated condition.

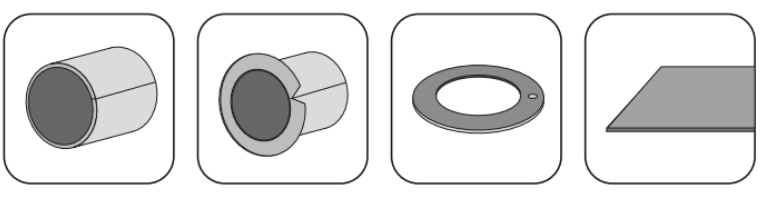

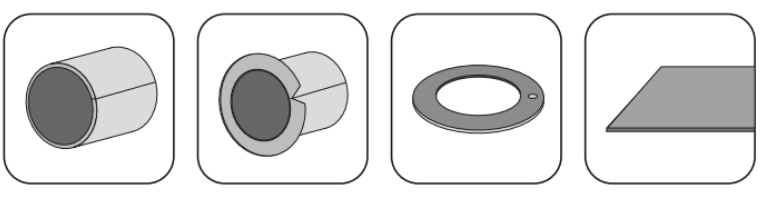

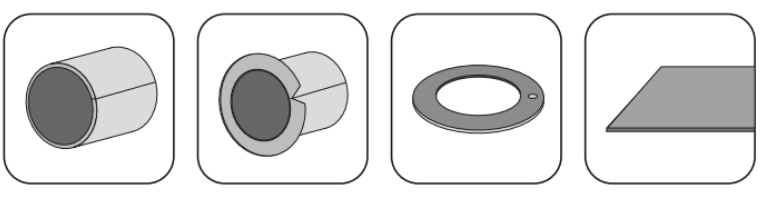

Available product shapesCylindrical bush, flanged bush, thrust washer and slide plate are regular shapes. For detailed dimensions, please check out size tables. Custom shapes or dimensions are made on request.

Typical applications

Typical applicationsGeneral Industry

–construction equipment, agricultural equipment,forming machines, handling equipment,food and beverage,office equipment,pharmaceutical and scientific equipment,packaging machinery,textile machinery,pumps,valves,pneumatic and hydraulic cylinders, and motors,etc.

Vehicle

–brake caliper, gearbox and transmissions, door hinges,bonnet, boot, pedals, pumps(gear pump,piston pump and vane pump); seat mechanisms, steering systems, struts and shock absorbers, wiper systems, etc.

In the electrolytic cell filled with electrolyte into the direct current, water molecules in the electrode electrochemical reaction, can be decomposed into hydrogen and oxygen, the whole process can achieve zero emissions. In the whole manufacturing process, the core equipment carrier is the electrolytic cell. Usually, the structure of the electrolytic cell is composed of three parts, namely, the tank body, the anode and the cathode. When direct current passes through the electrolytic cell, an oxidation reaction occurs at the interface between the anode and the solution, and a reduction reaction occurs at the interface between the cathode and the solution. At present, China's electrolytic water hydrogen production equipment is mostly used in photovoltaic, wind power, renewable energy hydrogen production is the main direction.

MP10

Multi-line text content element

HTML language content can be parsed after rich text content is bound to data

Classification:

Metal-Polymer Composite Bearings

Key words: Electrolyzed water equipment

- DESCRIPTION

-

Product introduction

MP10 is a type of metal-polymer composite of trilayer structure, designed for dry operation. Low carbon steel is used as its backing material. Under high temperature, a layer of bronze powder is firstly sintered onto the steel backing as inter-layer and subsequently the lining layer(mixture of PTFE and fillers) is sintered onto the bronze layer. The steel backing can provide powerful support, ensuring dimensional stability for the bearing. The porous bronze layer serves as carrier and retainer for the lining, providing function of heat dissipation. This scientific design of structure enables MP10 to have excellent tribological properties.

When a MP10 bearing operates, in the running-in period, a surge of coefficient of friction normally occurs within a short time and some of the polymer would be transferred to the mating surface,forming a solid lubricating film. Over the next normal operation period, the coefficient of friction can be at a very low level for a long time and the solid lubricating film can maintain there until the end of bearing service life.

During operation, stick-slip phenomenon is negligible due to the excellent lubricity of the polymer. It can be satisfactorily compatible with external materials. So that, MP10 can operate well even in dusty working condition. Also MP10 can be used in the most fluids which does not chemically attack the bearing material, such as water, lubricating oil, engine oil, turbine oil, hydraulic oil, solvent,refrigerants. As a matter of fact, under lubricated condition. It performs better with lower coefficient of friction, lower wear rate and can endure higher PV value.

Material structure and composition

①lining layer ( mixture of PTFE and fillers),0.01-0.03mm thick.

②porous bronze sinter layer, 0.20-0.30mm thick.

③steel backing ,copper-plated or tin-plated.

PropertiesParameter Condition Value Max. load Static 250N/mm² Dynamic 140N/mm² Max.speed Dry 2.5m/s Oil 5m/s Max.PV (dry) Short time 3.6N/mm²*m/s Long time 1.8N/mm²*m/s Temperature range ℃~+280℃ Coefficient of friction 0.03-0.20 Thermal conductivity 42W(m*K)-1 Coefficient of linear thermal expansion 11*10-6*K-1 Product Features-Quiet operation.

-Capable of dry operation without lubrication.

-Suitable for linear, rotating and oscillating movements.

-Low friction and high wear resistance

-Excellent anti-corrosion and chemical resistance.

-Lead-free, compliant to RoHS specifications.

-Simple and compact structure, reducing size and weight, easy installment.

-Performance improves in lubricated condition.

Available product shapesCylindrical bush, flanged bush, thrust washer and slide plate are regular shapes. For detailed dimensions, please check out size tables. Custom shapes or dimensions are made on request.

Typical applications

Typical applicationsGeneral Industry

–construction equipment, agricultural equipment,forming machines, handling equipment,food and beverage,office equipment,pharmaceutical and scientific equipment,packaging machinery,textile machinery,pumps,valves,pneumatic and hydraulic cylinders, and motors,etc.

Vehicle

–brake caliper, gearbox and transmissions, door hinges,bonnet, boot, pedals, pumps(gear pump,piston pump and vane pump); seat mechanisms, steering systems, struts and shock absorbers, wiper systems, etc.

In the electrolytic cell filled with electrolyte into the direct current, water molecules in the electrode electrochemical reaction, can be decomposed into hydrogen and oxygen, the whole process can achieve zero emissions. In the whole manufacturing process, the core equipment carrier is the electrolytic cell. Usually, the structure of the electrolytic cell is composed of three parts, namely, the tank body, the anode and the cathode. When direct current passes through the electrolytic cell, an oxidation reaction occurs at the interface between the anode and the solution, and a reduction reaction occurs at the interface between the cathode and the solution. At present, China's electrolytic water hydrogen production equipment is mostly used in photovoltaic, wind power, renewable energy hydrogen production is the main direction.

ORDER ONLINE

Filling in your phone and email information will help us to contact you in a timely manner and resolve your issue as soon as possible.

- DESCRIPTION

-

Product introduction

MP10 is a type of metal-polymer composite of trilayer structure, designed for dry operation. Low carbon steel is used as its backing material. Under high temperature, a layer of bronze powder is firstly sintered onto the steel backing as inter-layer and subsequently the lining layer(mixture of PTFE and fillers) is sintered onto the bronze layer. The steel backing can provide powerful support, ensuring dimensional stability for the bearing. The porous bronze layer serves as carrier and retainer for the lining, providing function of heat dissipation. This scientific design of structure enables MP10 to have excellent tribological properties.

When a MP10 bearing operates, in the running-in period, a surge of coefficient of friction normally occurs within a short time and some of the polymer would be transferred to the mating surface,forming a solid lubricating film. Over the next normal operation period, the coefficient of friction can be at a very low level for a long time and the solid lubricating film can maintain there until the end of bearing service life.

During operation, stick-slip phenomenon is negligible due to the excellent lubricity of the polymer. It can be satisfactorily compatible with external materials. So that, MP10 can operate well even in dusty working condition. Also MP10 can be used in the most fluids which does not chemically attack the bearing material, such as water, lubricating oil, engine oil, turbine oil, hydraulic oil, solvent,refrigerants. As a matter of fact, under lubricated condition. It performs better with lower coefficient of friction, lower wear rate and can endure higher PV value.

Material structure and composition

①lining layer ( mixture of PTFE and fillers),0.01-0.03mm thick.

②porous bronze sinter layer, 0.20-0.30mm thick.

③steel backing ,copper-plated or tin-plated.

PropertiesParameter Condition Value Max. load Static 250N/mm² Dynamic 140N/mm² Max.speed Dry 2.5m/s Oil 5m/s Max.PV (dry) Short time 3.6N/mm²*m/s Long time 1.8N/mm²*m/s Temperature range ℃~+280℃ Coefficient of friction 0.03-0.20 Thermal conductivity 42W(m*K)-1 Coefficient of linear thermal expansion 11*10-6*K-1 Product Features-Quiet operation.

-Capable of dry operation without lubrication.

-Suitable for linear, rotating and oscillating movements.

-Low friction and high wear resistance

-Excellent anti-corrosion and chemical resistance.

-Lead-free, compliant to RoHS specifications.

-Simple and compact structure, reducing size and weight, easy installment.

-Performance improves in lubricated condition.

Available product shapesCylindrical bush, flanged bush, thrust washer and slide plate are regular shapes. For detailed dimensions, please check out size tables. Custom shapes or dimensions are made on request.

Typical applications

Typical applicationsGeneral Industry

–construction equipment, agricultural equipment,forming machines, handling equipment,food and beverage,office equipment,pharmaceutical and scientific equipment,packaging machinery,textile machinery,pumps,valves,pneumatic and hydraulic cylinders, and motors,etc.

Vehicle

–brake caliper, gearbox and transmissions, door hinges,bonnet, boot, pedals, pumps(gear pump,piston pump and vane pump); seat mechanisms, steering systems, struts and shock absorbers, wiper systems, etc.

In the electrolytic cell filled with electrolyte into the direct current, water molecules in the electrode electrochemical reaction, can be decomposed into hydrogen and oxygen, the whole process can achieve zero emissions. In the whole manufacturing process, the core equipment carrier is the electrolytic cell. Usually, the structure of the electrolytic cell is composed of three parts, namely, the tank body, the anode and the cathode. When direct current passes through the electrolytic cell, an oxidation reaction occurs at the interface between the anode and the solution, and a reduction reaction occurs at the interface between the cathode and the solution. At present, China's electrolytic water hydrogen production equipment is mostly used in photovoltaic, wind power, renewable energy hydrogen production is the main direction.