Hot Products For All Applications

MP20

Multi-line text content element

HTML language content can be parsed after rich text content is bound to data

Classification:

Products

Metal-Polymer Composite Bearings

Key words: Electrolyzed water equipment

- DESCRIPTION

-

Product introduction

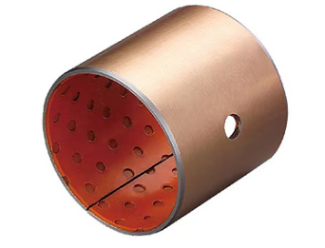

MP20 is a type of trilayer metal-polymer composite. Its backing layer and interlayer are as same as MP10. But its lining layer is modified POM instead of PTFE mixture. The steel backing provides powerful supporting strength and bronze sinter layer serves as carrier and retainer for the POM lining layer. By sintering in a heat furnace of a certain high temperature, the POM lining firmly sticks to the bronze sinter layer with part of them impregnated into the bronze sinter layer.

POM is highly crystalline polymer,which is one of engineering plastics with mechanical properties most similar to metals. The outstanding physical and chemical properties of POM normally include high hardness,good wear resistance,good fatigue strength, superior impact resistance and low water absorption rate. When it comes to MP20, the modified POM layer exhibites improved performance such as very low friction,minimal wear rate and extended service life.

MP20 is developed for boundary lubrication operation, therefore lubrication is necessary when installed. In order to make it get well lubricated during operation, the lining layer is often designed to have plenty of regularly arranged pockets. Lubricants like grease or oil can maintain there for a long time. This widely adopted and highly effective design of sustaining lubrication make lubrication cycle greatly extended, resulting in the significant reduction of maintenance and running cost.

.

Material structure and composition

①lining layer(modified POM),0.30-0.50mm thick.

②porous bronze sinter layer, 0.20-0.35mm thick.

③steel backing,copper-plated or tin-plated.

PropertiesParameter

Condition

Value

Max. load

Static

250N/mm²

Dynamic

140N/mm²

Max.speed

Grease

2.5m/s

oil

5m/s

Max. PV

Lubricated

2.8N/mm²*m/s

Coefficient of friction

Lubricated

0.01-0.20

Temperature range

-40℃~+130℃

Thermal conductivity

50W(m*K)-1

Coefficient of linear thermal expansion

11*10-6*K-1

Product features-Low maintenance.

-Resistant to contamination.

-Excellent corrosion resistance.

-Excellent wear resistance and low friction under relatively high load,low speed condition.

-Pre-lubrication is recommended , grease is preferred.

-Suitable for linear, oscillating and rotating movements.

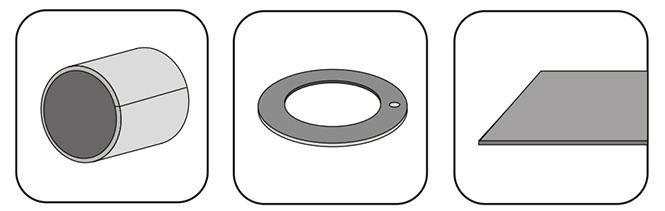

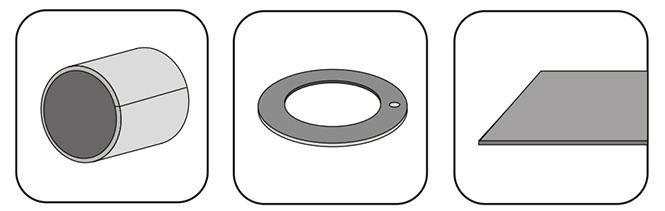

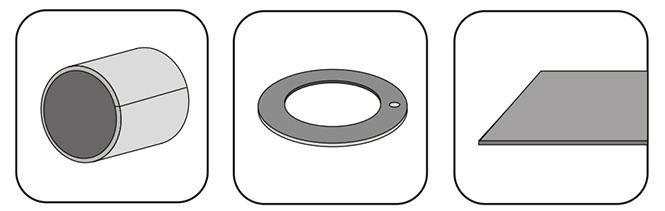

Available product shapesCylindrical bush, thrust washer and slide plate. For detailed dimensions, please check out size tables. Custom shapes and dimensions are made on request.

The color of the lining layer

The color of the lining layerThe color of the lining layer depends on the pigment which is a part of the modifiers. Usually ferric oxide is the most often used pigment. Yellow is the most popular color.

Typical applicationsVehicle,agricultural machinery, handling and lifting equipment,machine tool, building industry, engineering machinery,hydraulic system,etc.

In the electrolytic cell filled with electrolyte into the direct current, water molecules in the electrode electrochemical reaction, can be decomposed into hydrogen and oxygen, the whole process can achieve zero emissions. In the whole manufacturing process, the core equipment carrier is the electrolytic cell. Usually, the structure of the electrolytic cell is composed of three parts, namely, the tank body, the anode and the cathode. When direct current passes through the electrolytic cell, an oxidation reaction occurs at the interface between the anode and the solution, and a reduction reaction occurs at the interface between the cathode and the solution. At present, China's electrolytic water hydrogen production equipment is mostly used in photovoltaic, wind power, renewable energy hydrogen production is the main direction.

MP20

Multi-line text content element

HTML language content can be parsed after rich text content is bound to data

Classification:

Products

Metal-Polymer Composite Bearings

Key words: Electrolyzed water equipment

- DESCRIPTION

-

Product introduction

MP20 is a type of trilayer metal-polymer composite. Its backing layer and interlayer are as same as MP10. But its lining layer is modified POM instead of PTFE mixture. The steel backing provides powerful supporting strength and bronze sinter layer serves as carrier and retainer for the POM lining layer. By sintering in a heat furnace of a certain high temperature, the POM lining firmly sticks to the bronze sinter layer with part of them impregnated into the bronze sinter layer.

POM is highly crystalline polymer,which is one of engineering plastics with mechanical properties most similar to metals. The outstanding physical and chemical properties of POM normally include high hardness,good wear resistance,good fatigue strength, superior impact resistance and low water absorption rate. When it comes to MP20, the modified POM layer exhibites improved performance such as very low friction,minimal wear rate and extended service life.

MP20 is developed for boundary lubrication operation, therefore lubrication is necessary when installed. In order to make it get well lubricated during operation, the lining layer is often designed to have plenty of regularly arranged pockets. Lubricants like grease or oil can maintain there for a long time. This widely adopted and highly effective design of sustaining lubrication make lubrication cycle greatly extended, resulting in the significant reduction of maintenance and running cost.

.

Material structure and composition

①lining layer(modified POM),0.30-0.50mm thick.

②porous bronze sinter layer, 0.20-0.35mm thick.

③steel backing,copper-plated or tin-plated.

PropertiesParameter

Condition

Value

Max. load

Static

250N/mm²

Dynamic

140N/mm²

Max.speed

Grease

2.5m/s

oil

5m/s

Max. PV

Lubricated

2.8N/mm²*m/s

Coefficient of friction

Lubricated

0.01-0.20

Temperature range

-40℃~+130℃

Thermal conductivity

50W(m*K)-1

Coefficient of linear thermal expansion

11*10-6*K-1

Product features-Low maintenance.

-Resistant to contamination.

-Excellent corrosion resistance.

-Excellent wear resistance and low friction under relatively high load,low speed condition.

-Pre-lubrication is recommended , grease is preferred.

-Suitable for linear, oscillating and rotating movements.

Available product shapesCylindrical bush, thrust washer and slide plate. For detailed dimensions, please check out size tables. Custom shapes and dimensions are made on request.

The color of the lining layer

The color of the lining layerThe color of the lining layer depends on the pigment which is a part of the modifiers. Usually ferric oxide is the most often used pigment. Yellow is the most popular color.

Typical applicationsVehicle,agricultural machinery, handling and lifting equipment,machine tool, building industry, engineering machinery,hydraulic system,etc.

In the electrolytic cell filled with electrolyte into the direct current, water molecules in the electrode electrochemical reaction, can be decomposed into hydrogen and oxygen, the whole process can achieve zero emissions. In the whole manufacturing process, the core equipment carrier is the electrolytic cell. Usually, the structure of the electrolytic cell is composed of three parts, namely, the tank body, the anode and the cathode. When direct current passes through the electrolytic cell, an oxidation reaction occurs at the interface between the anode and the solution, and a reduction reaction occurs at the interface between the cathode and the solution. At present, China's electrolytic water hydrogen production equipment is mostly used in photovoltaic, wind power, renewable energy hydrogen production is the main direction.

ORDER ONLINE

Filling in your phone and email information will help us to contact you in a timely manner and resolve your issue as soon as possible.

- DESCRIPTION

-

Product introduction

MP20 is a type of trilayer metal-polymer composite. Its backing layer and interlayer are as same as MP10. But its lining layer is modified POM instead of PTFE mixture. The steel backing provides powerful supporting strength and bronze sinter layer serves as carrier and retainer for the POM lining layer. By sintering in a heat furnace of a certain high temperature, the POM lining firmly sticks to the bronze sinter layer with part of them impregnated into the bronze sinter layer.

POM is highly crystalline polymer,which is one of engineering plastics with mechanical properties most similar to metals. The outstanding physical and chemical properties of POM normally include high hardness,good wear resistance,good fatigue strength, superior impact resistance and low water absorption rate. When it comes to MP20, the modified POM layer exhibites improved performance such as very low friction,minimal wear rate and extended service life.

MP20 is developed for boundary lubrication operation, therefore lubrication is necessary when installed. In order to make it get well lubricated during operation, the lining layer is often designed to have plenty of regularly arranged pockets. Lubricants like grease or oil can maintain there for a long time. This widely adopted and highly effective design of sustaining lubrication make lubrication cycle greatly extended, resulting in the significant reduction of maintenance and running cost.

.

Material structure and composition

①lining layer(modified POM),0.30-0.50mm thick.

②porous bronze sinter layer, 0.20-0.35mm thick.

③steel backing,copper-plated or tin-plated.

PropertiesParameter

Condition

Value

Max. load

Static

250N/mm²

Dynamic

140N/mm²

Max.speed

Grease

2.5m/s

oil

5m/s

Max. PV

Lubricated

2.8N/mm²*m/s

Coefficient of friction

Lubricated

0.01-0.20

Temperature range

-40℃~+130℃

Thermal conductivity

50W(m*K)-1

Coefficient of linear thermal expansion

11*10-6*K-1

Product features-Low maintenance.

-Resistant to contamination.

-Excellent corrosion resistance.

-Excellent wear resistance and low friction under relatively high load,low speed condition.

-Pre-lubrication is recommended , grease is preferred.

-Suitable for linear, oscillating and rotating movements.

Available product shapesCylindrical bush, thrust washer and slide plate. For detailed dimensions, please check out size tables. Custom shapes and dimensions are made on request.

The color of the lining layer

The color of the lining layerThe color of the lining layer depends on the pigment which is a part of the modifiers. Usually ferric oxide is the most often used pigment. Yellow is the most popular color.

Typical applicationsVehicle,agricultural machinery, handling and lifting equipment,machine tool, building industry, engineering machinery,hydraulic system,etc.

In the electrolytic cell filled with electrolyte into the direct current, water molecules in the electrode electrochemical reaction, can be decomposed into hydrogen and oxygen, the whole process can achieve zero emissions. In the whole manufacturing process, the core equipment carrier is the electrolytic cell. Usually, the structure of the electrolytic cell is composed of three parts, namely, the tank body, the anode and the cathode. When direct current passes through the electrolytic cell, an oxidation reaction occurs at the interface between the anode and the solution, and a reduction reaction occurs at the interface between the cathode and the solution. At present, China's electrolytic water hydrogen production equipment is mostly used in photovoltaic, wind power, renewable energy hydrogen production is the main direction.