Hot Products For All Applications

GCB

Multi-line text content element

HTML language content can be parsed after rich text content is bound to data

Classification:

Products

Metal Bearings

Key words: Electrolyzed water equipment

- DESCRIPTION

-

Product introduction

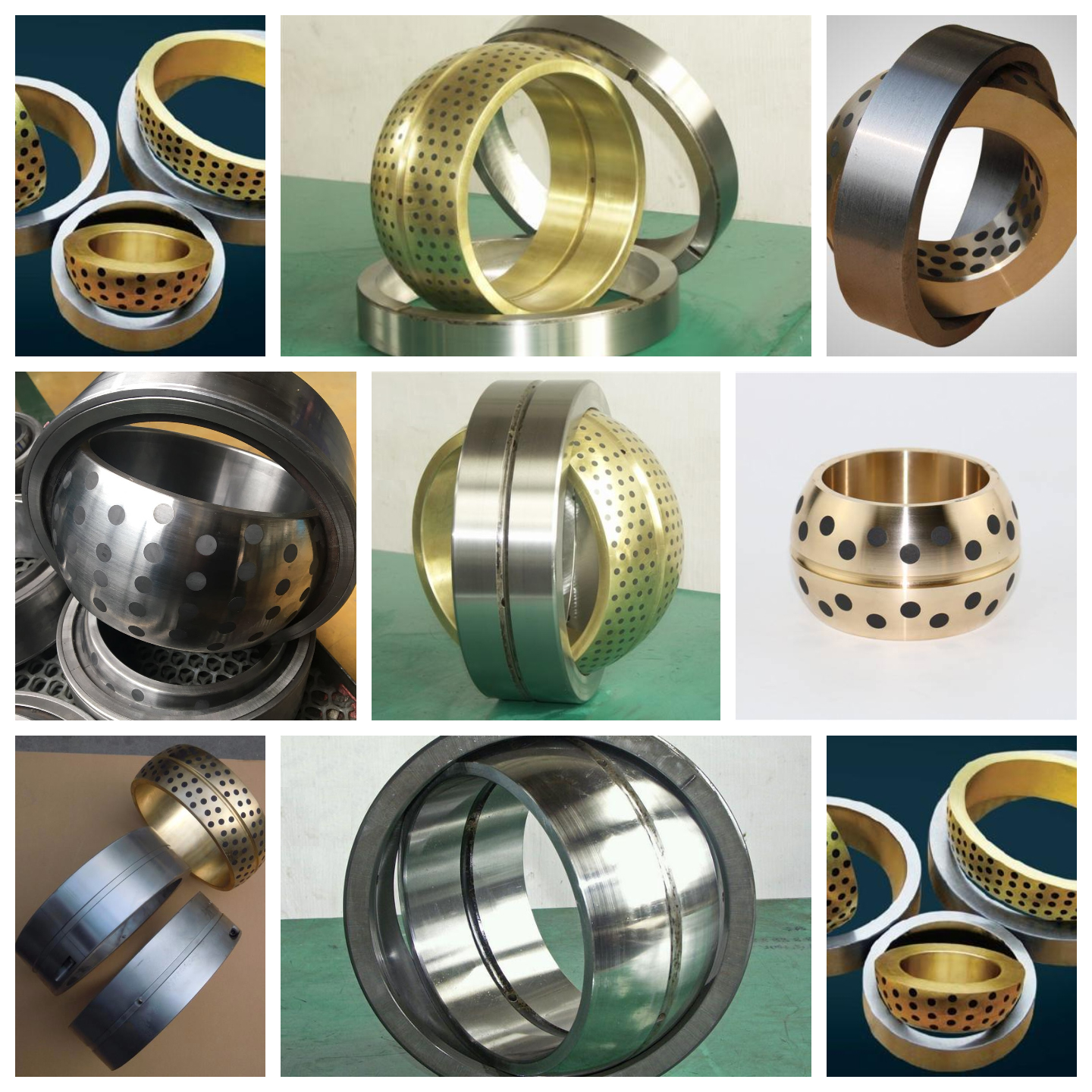

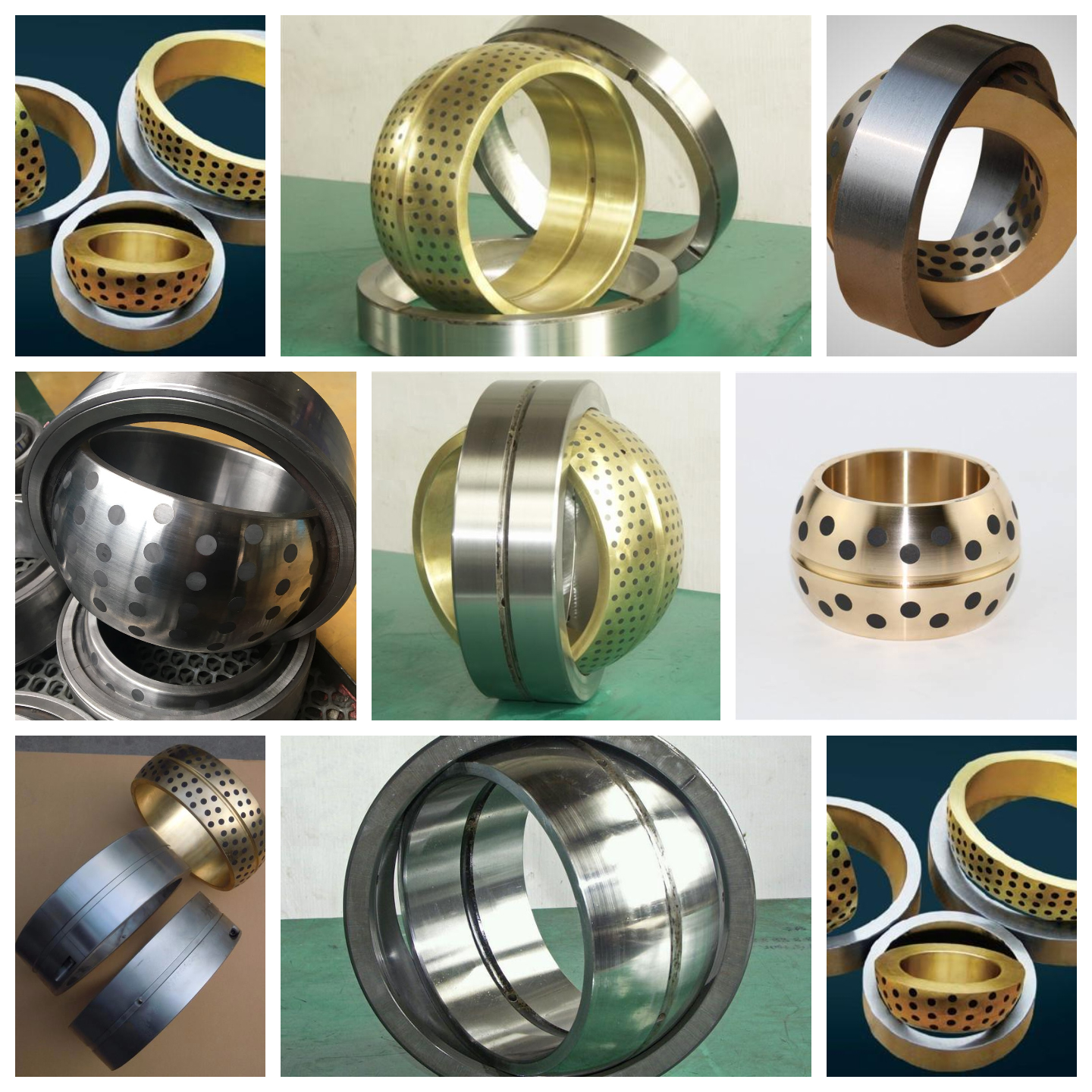

GCB consists of cast copper alloy and solid lubricant. The high strength copper alloys have outstanding corrosion resistance, excellent lubricity and thermal conductivity, can provide powerful structural support. Solid lubricants of high lubricity are orderly arranged across the working surface of bronze support in a certain proportion. With specially designed solid lubricants, GCB can be used in wet, dirty environments and exposed to seawater.

During normal operation, solid lubricants can be continuously released and supplied to mating surfaces, so that solid lubricating film can be maintained there until the end of bearing service life. This unique material structure and lubrication method enable GCB to have excellent self-lubrication property and perform very well with very low friction, minimal wear, long time service life.

Compared to conventional lubricated metallic bearings, GCB bearings can perform better in the situations where conventional external lubrication with grease or oil is unfeasible because liquid lubricant may be squeezed out of the contact area due to heavy load during long-time dwell time, or even under normal rotating or oscillating movement. The shortage of lubricant often results in severe friction and wear, even premature bearing failure. So that ,GCB becomes the ideal replacement for conventional lubricated bearings in these cases.

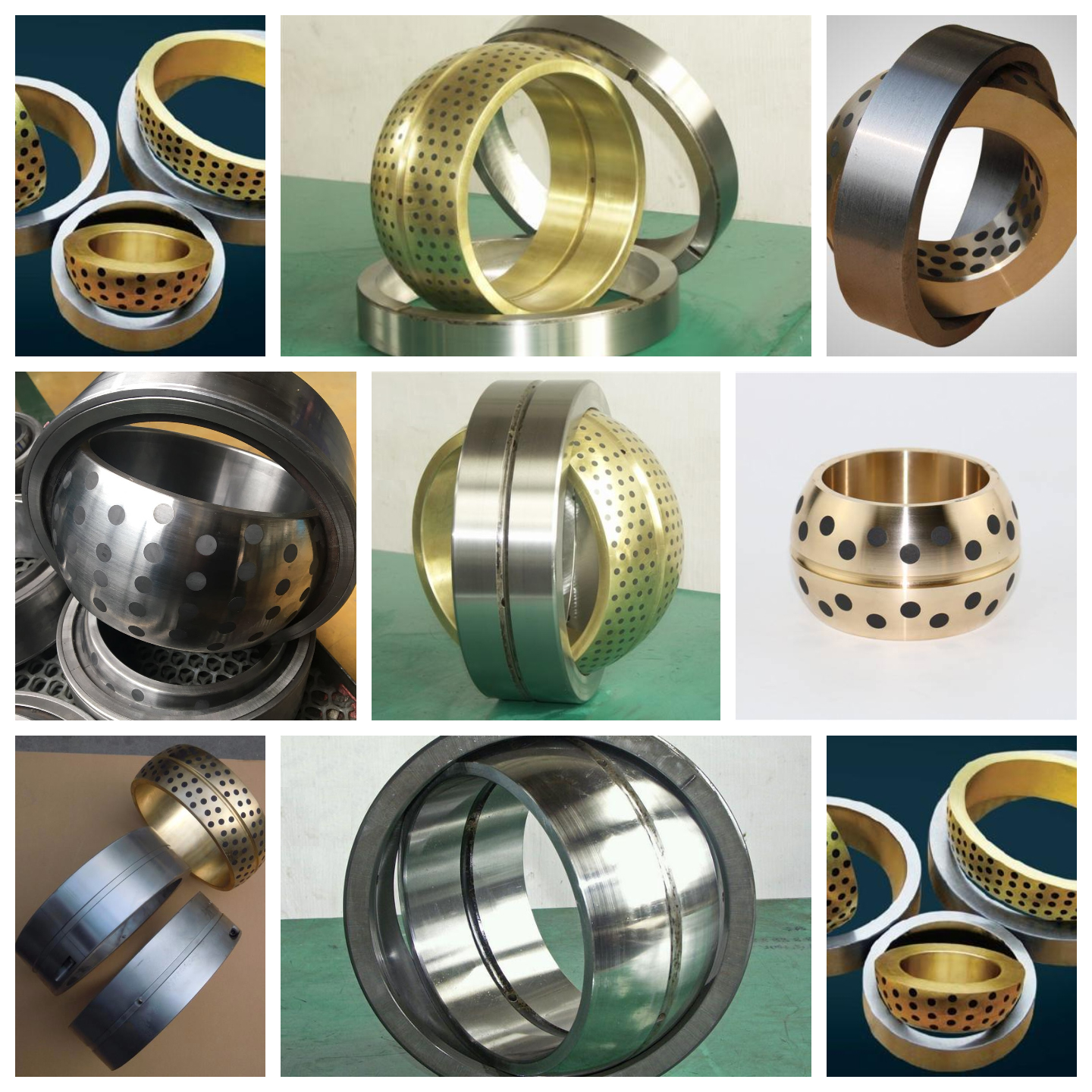

To fully make use of the advantages of GCB and solid lubricant, we also have developed self-aligning spherical plain bearings( or named radial spherical plain bearings). A self-aligning spherical plain bearing is composed of an inner ring with sphered convex outside diameter and an outer ring with a correspondingly sphered but concave inside surface. This design makes it particularly suitable for the applications where disalignment motion or circumferential oscillating motion between shaft and housing often occures at relatively slow sliding speeds. These products can be made according to detailed technical drawings. Out rings are high performance bearing steel. Inner rings can be GCB or bearing steel.

Product features

Product features-High performance under heavy load and low speed operations.

-Self-lubricating,maintenance-free,saving running cost.

-Superior wear resistance in applications where oil film is hard to come into being ,such as reciprocating motion, oscillation,intermittent motion, frequent starts and stops,etc.

-Superior chemical resistance and corrosion resistance.

-Underwater operation are applicable by leveraging special solid lubricants.

-Various sizes and shapes can be made by means of casting technique.

Available copper alloys and propertiesProduct Type

GCB63

GCB75

GCB80

GCB88

Alloy Designation

CuZn25AI5Mn4Fe3

CuSn5Pb5Zn5

CuAl10Ni5Fe5

CuSn12

Density(g/cm³)

7.9

8.9

7.8

8.9

Hardness(HB)

≥210

≥70

≥150

≥75

Tensile Strength(MPa)

≥755

≥250

≥500

≥270

Yield Strength (MPa)

≥450

≥90

≥260

≥150

Elongation at break( %)

≥12

≥13

≥10

≥5

Thermal Expansion Coefficient

1.9x10*%/°C

1.8x10*9/°C

1.6x10^*/°C

1.8x10*/°C

Temperature Range

-40~+300°C

-40~+400°C

-40~+400°C

-40~+400°C

Max. Load (MPa)

100

50

50

50

Max.Speed(m/s)

Dry

0.5

0.5

0.5

0.5

Lubricated

1

2.5

2.5

2.5

Max. PV (N/mm²*m/s)

Dry

1.65

1

1

1

Lubricated

3.25

1.65

1.65

1.65

Solid lubricant

We offer two types of solid lubricants to meet different operation conditions. They are graphite-based( SL-A) and PTFE-based (SL-B) respectively. The former is most often used, but not supposed to be used where electrolytic corrosion could occurs, such as in high humidity atmospheres or underwater equipment. In this case, PTFE-based solid lubricant is the priority choice.

SL-A : mixture of graphite and additives, can endure up to +400℃,suitable for general purpose use in the atmosphere.

SL-B : mixture of PTFE and additives, can endure up to +300℃,for underwater,undersea or marine applications.

The solid lubricants are of high density and superior lubricity, available with different colors, such as black,grey,white or blue, depending upon the additives that mixed with graphite or PTFE.

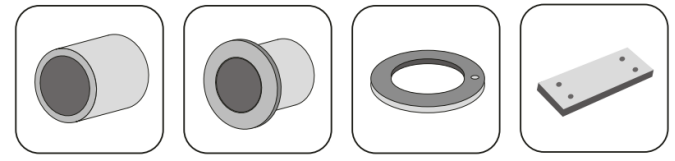

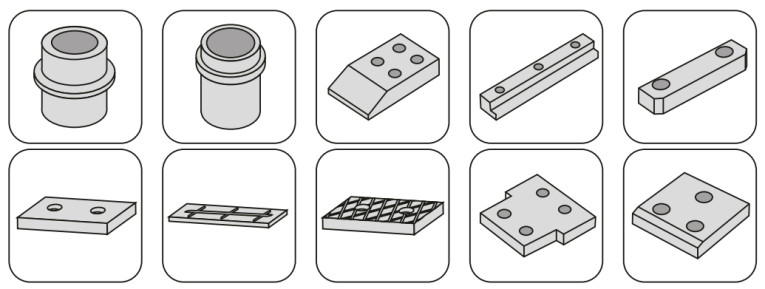

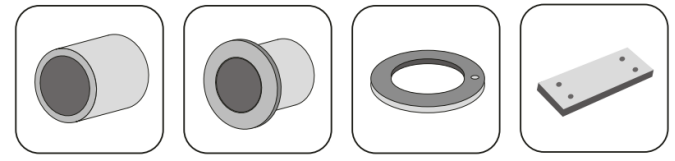

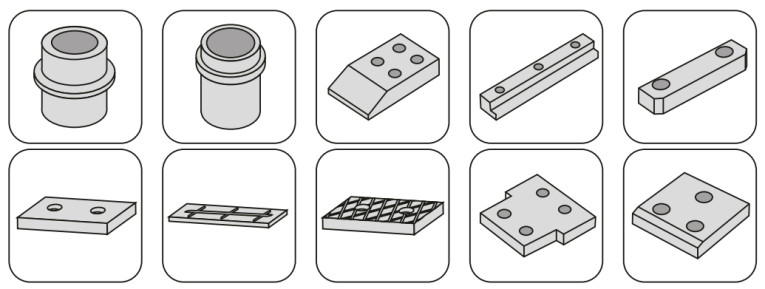

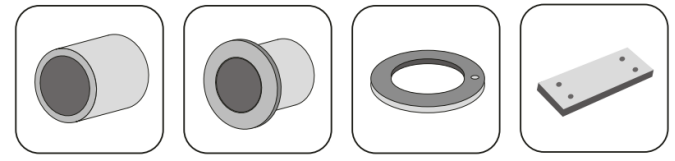

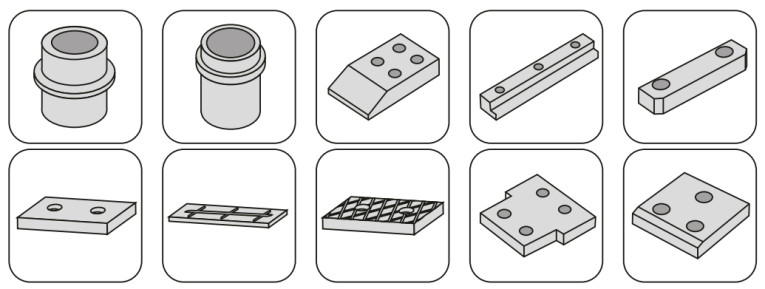

Available product shapesThe products are made as per technical drawings. Regular shapes are as shown below. For standard size,please check out our size tables.

Typical applications

Typical applicationsInjection molding machine,press machine,punching machine,forging machine, die and mold, engineering machinery, agriculture machinery,mining machinery,metallurgy machinery,hydraulic power plant, bridge, cable-stayed suspension bridge,marine drilling platform,marine machinery, port machinery,hydraulic cylinder,etc.

In the electrolytic cell filled with electrolyte into the direct current, water molecules in the electrode electrochemical reaction, can be decomposed into hydrogen and oxygen, the whole process can achieve zero emissions. In the whole manufacturing process, the core equipment carrier is the electrolytic cell. Usually, the structure of the electrolytic cell is composed of three parts, namely, the tank body, the anode and the cathode. When direct current passes through the electrolytic cell, an oxidation reaction occurs at the interface between the anode and the solution, and a reduction reaction occurs at the interface between the cathode and the solution. At present, China's electrolytic water hydrogen production equipment is mostly used in photovoltaic, wind power, renewable energy hydrogen production is the main direction.

GCB

Multi-line text content element

HTML language content can be parsed after rich text content is bound to data

Classification:

Products

Metal Bearings

Key words: Electrolyzed water equipment

- DESCRIPTION

-

Product introduction

GCB consists of cast copper alloy and solid lubricant. The high strength copper alloys have outstanding corrosion resistance, excellent lubricity and thermal conductivity, can provide powerful structural support. Solid lubricants of high lubricity are orderly arranged across the working surface of bronze support in a certain proportion. With specially designed solid lubricants, GCB can be used in wet, dirty environments and exposed to seawater.

During normal operation, solid lubricants can be continuously released and supplied to mating surfaces, so that solid lubricating film can be maintained there until the end of bearing service life. This unique material structure and lubrication method enable GCB to have excellent self-lubrication property and perform very well with very low friction, minimal wear, long time service life.

Compared to conventional lubricated metallic bearings, GCB bearings can perform better in the situations where conventional external lubrication with grease or oil is unfeasible because liquid lubricant may be squeezed out of the contact area due to heavy load during long-time dwell time, or even under normal rotating or oscillating movement. The shortage of lubricant often results in severe friction and wear, even premature bearing failure. So that ,GCB becomes the ideal replacement for conventional lubricated bearings in these cases.

To fully make use of the advantages of GCB and solid lubricant, we also have developed self-aligning spherical plain bearings( or named radial spherical plain bearings). A self-aligning spherical plain bearing is composed of an inner ring with sphered convex outside diameter and an outer ring with a correspondingly sphered but concave inside surface. This design makes it particularly suitable for the applications where disalignment motion or circumferential oscillating motion between shaft and housing often occures at relatively slow sliding speeds. These products can be made according to detailed technical drawings. Out rings are high performance bearing steel. Inner rings can be GCB or bearing steel.

Product features

Product features-High performance under heavy load and low speed operations.

-Self-lubricating,maintenance-free,saving running cost.

-Superior wear resistance in applications where oil film is hard to come into being ,such as reciprocating motion, oscillation,intermittent motion, frequent starts and stops,etc.

-Superior chemical resistance and corrosion resistance.

-Underwater operation are applicable by leveraging special solid lubricants.

-Various sizes and shapes can be made by means of casting technique.

Available copper alloys and propertiesProduct Type

GCB63

GCB75

GCB80

GCB88

Alloy Designation

CuZn25AI5Mn4Fe3

CuSn5Pb5Zn5

CuAl10Ni5Fe5

CuSn12

Density(g/cm³)

7.9

8.9

7.8

8.9

Hardness(HB)

≥210

≥70

≥150

≥75

Tensile Strength(MPa)

≥755

≥250

≥500

≥270

Yield Strength (MPa)

≥450

≥90

≥260

≥150

Elongation at break( %)

≥12

≥13

≥10

≥5

Thermal Expansion Coefficient

1.9x10*%/°C

1.8x10*9/°C

1.6x10^*/°C

1.8x10*/°C

Temperature Range

-40~+300°C

-40~+400°C

-40~+400°C

-40~+400°C

Max. Load (MPa)

100

50

50

50

Max.Speed(m/s)

Dry

0.5

0.5

0.5

0.5

Lubricated

1

2.5

2.5

2.5

Max. PV (N/mm²*m/s)

Dry

1.65

1

1

1

Lubricated

3.25

1.65

1.65

1.65

Solid lubricant

We offer two types of solid lubricants to meet different operation conditions. They are graphite-based( SL-A) and PTFE-based (SL-B) respectively. The former is most often used, but not supposed to be used where electrolytic corrosion could occurs, such as in high humidity atmospheres or underwater equipment. In this case, PTFE-based solid lubricant is the priority choice.

SL-A : mixture of graphite and additives, can endure up to +400℃,suitable for general purpose use in the atmosphere.

SL-B : mixture of PTFE and additives, can endure up to +300℃,for underwater,undersea or marine applications.

The solid lubricants are of high density and superior lubricity, available with different colors, such as black,grey,white or blue, depending upon the additives that mixed with graphite or PTFE.

Available product shapesThe products are made as per technical drawings. Regular shapes are as shown below. For standard size,please check out our size tables.

Typical applications

Typical applicationsInjection molding machine,press machine,punching machine,forging machine, die and mold, engineering machinery, agriculture machinery,mining machinery,metallurgy machinery,hydraulic power plant, bridge, cable-stayed suspension bridge,marine drilling platform,marine machinery, port machinery,hydraulic cylinder,etc.

In the electrolytic cell filled with electrolyte into the direct current, water molecules in the electrode electrochemical reaction, can be decomposed into hydrogen and oxygen, the whole process can achieve zero emissions. In the whole manufacturing process, the core equipment carrier is the electrolytic cell. Usually, the structure of the electrolytic cell is composed of three parts, namely, the tank body, the anode and the cathode. When direct current passes through the electrolytic cell, an oxidation reaction occurs at the interface between the anode and the solution, and a reduction reaction occurs at the interface between the cathode and the solution. At present, China's electrolytic water hydrogen production equipment is mostly used in photovoltaic, wind power, renewable energy hydrogen production is the main direction.

ORDER ONLINE

Filling in your phone and email information will help us to contact you in a timely manner and resolve your issue as soon as possible.

- DESCRIPTION

-

Product introduction

GCB consists of cast copper alloy and solid lubricant. The high strength copper alloys have outstanding corrosion resistance, excellent lubricity and thermal conductivity, can provide powerful structural support. Solid lubricants of high lubricity are orderly arranged across the working surface of bronze support in a certain proportion. With specially designed solid lubricants, GCB can be used in wet, dirty environments and exposed to seawater.

During normal operation, solid lubricants can be continuously released and supplied to mating surfaces, so that solid lubricating film can be maintained there until the end of bearing service life. This unique material structure and lubrication method enable GCB to have excellent self-lubrication property and perform very well with very low friction, minimal wear, long time service life.

Compared to conventional lubricated metallic bearings, GCB bearings can perform better in the situations where conventional external lubrication with grease or oil is unfeasible because liquid lubricant may be squeezed out of the contact area due to heavy load during long-time dwell time, or even under normal rotating or oscillating movement. The shortage of lubricant often results in severe friction and wear, even premature bearing failure. So that ,GCB becomes the ideal replacement for conventional lubricated bearings in these cases.

To fully make use of the advantages of GCB and solid lubricant, we also have developed self-aligning spherical plain bearings( or named radial spherical plain bearings). A self-aligning spherical plain bearing is composed of an inner ring with sphered convex outside diameter and an outer ring with a correspondingly sphered but concave inside surface. This design makes it particularly suitable for the applications where disalignment motion or circumferential oscillating motion between shaft and housing often occures at relatively slow sliding speeds. These products can be made according to detailed technical drawings. Out rings are high performance bearing steel. Inner rings can be GCB or bearing steel.

Product features

Product features-High performance under heavy load and low speed operations.

-Self-lubricating,maintenance-free,saving running cost.

-Superior wear resistance in applications where oil film is hard to come into being ,such as reciprocating motion, oscillation,intermittent motion, frequent starts and stops,etc.

-Superior chemical resistance and corrosion resistance.

-Underwater operation are applicable by leveraging special solid lubricants.

-Various sizes and shapes can be made by means of casting technique.

Available copper alloys and propertiesProduct Type

GCB63

GCB75

GCB80

GCB88

Alloy Designation

CuZn25AI5Mn4Fe3

CuSn5Pb5Zn5

CuAl10Ni5Fe5

CuSn12

Density(g/cm³)

7.9

8.9

7.8

8.9

Hardness(HB)

≥210

≥70

≥150

≥75

Tensile Strength(MPa)

≥755

≥250

≥500

≥270

Yield Strength (MPa)

≥450

≥90

≥260

≥150

Elongation at break( %)

≥12

≥13

≥10

≥5

Thermal Expansion Coefficient

1.9x10*%/°C

1.8x10*9/°C

1.6x10^*/°C

1.8x10*/°C

Temperature Range

-40~+300°C

-40~+400°C

-40~+400°C

-40~+400°C

Max. Load (MPa)

100

50

50

50

Max.Speed(m/s)

Dry

0.5

0.5

0.5

0.5

Lubricated

1

2.5

2.5

2.5

Max. PV (N/mm²*m/s)

Dry

1.65

1

1

1

Lubricated

3.25

1.65

1.65

1.65

Solid lubricant

We offer two types of solid lubricants to meet different operation conditions. They are graphite-based( SL-A) and PTFE-based (SL-B) respectively. The former is most often used, but not supposed to be used where electrolytic corrosion could occurs, such as in high humidity atmospheres or underwater equipment. In this case, PTFE-based solid lubricant is the priority choice.

SL-A : mixture of graphite and additives, can endure up to +400℃,suitable for general purpose use in the atmosphere.

SL-B : mixture of PTFE and additives, can endure up to +300℃,for underwater,undersea or marine applications.

The solid lubricants are of high density and superior lubricity, available with different colors, such as black,grey,white or blue, depending upon the additives that mixed with graphite or PTFE.

Available product shapesThe products are made as per technical drawings. Regular shapes are as shown below. For standard size,please check out our size tables.

Typical applications

Typical applicationsInjection molding machine,press machine,punching machine,forging machine, die and mold, engineering machinery, agriculture machinery,mining machinery,metallurgy machinery,hydraulic power plant, bridge, cable-stayed suspension bridge,marine drilling platform,marine machinery, port machinery,hydraulic cylinder,etc.

In the electrolytic cell filled with electrolyte into the direct current, water molecules in the electrode electrochemical reaction, can be decomposed into hydrogen and oxygen, the whole process can achieve zero emissions. In the whole manufacturing process, the core equipment carrier is the electrolytic cell. Usually, the structure of the electrolytic cell is composed of three parts, namely, the tank body, the anode and the cathode. When direct current passes through the electrolytic cell, an oxidation reaction occurs at the interface between the anode and the solution, and a reduction reaction occurs at the interface between the cathode and the solution. At present, China's electrolytic water hydrogen production equipment is mostly used in photovoltaic, wind power, renewable energy hydrogen production is the main direction.