Hot Products For All Applications

MCB

Multi-line text content element

HTML language content can be parsed after rich text content is bound to data

Classification:

Products

Metal Bearings

Key words: Electrolyzed water equipment

- DESCRIPTION

-

Product Introduction

MCB bearings are typical metallic bearings, designed for boundary lubrication operation.They are made of cast copper alloys.The alloy types are same with the ones of GCB. The difference is that no solid lubricants are inlaid into their bodies. To make the bushings well lubricated during operation,they are usually machined to have specific lubrication grooves at their inner surfaces. MCB bearings have excellent corrosion resistance and thermal conductivity. They are suitable for low speed, middle to high load applications. Under lubricated condition, they can perform very well due to the high strength and excellent lubricity of copper alloy.

Copper alloys and propertiesProduct Type

MCB63

MCB85

MCB80

MCB88

Alloy designation

CuZn25AI5Mn4Fe3

CuSn5Pb5Zn5

CuAl10Ni5Fe5

CuSn12

Density(g/cm³)

7.9

8.9

7.8

8.9

Hardness(HB)

≥210

≥70

≥150

≥75

Tensile Strength(MPa)

≥755

≥250

≥500

≥270

Yield Strength (MPa)

≥450

≥90

≥260

≥150

Elongation at break( %)

≥12

≥13

≥10

≥5

Thermal Expansion Coefficient

1.9x10*%/°C

1.8x10*9/°C

1.6x10^*/°C

1.8x10*/°C

Temperature range

-40~+300°C

-40~+400°C

-40~+400°C

-40~+400°C

Max. load (MPa)

100

50

50

50

Max.speed(m/s)

Dry

0.5

0.5

0.5

0.5

Lubricated

1

2.5

2.5

2.5

Max. PV (N/mm²*m/s)

Dry

1.65

1

1

1

Lubricated

3.25

1.65

1.65

1.65

Note: more copper alloys are made on request.

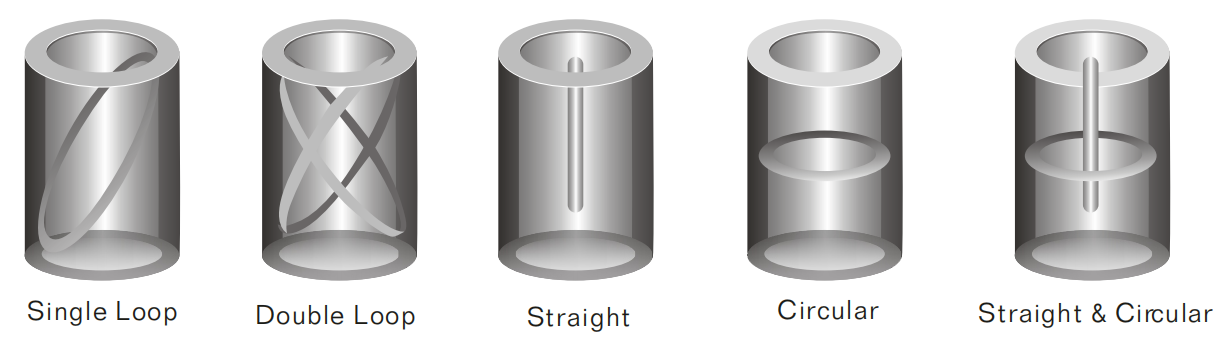

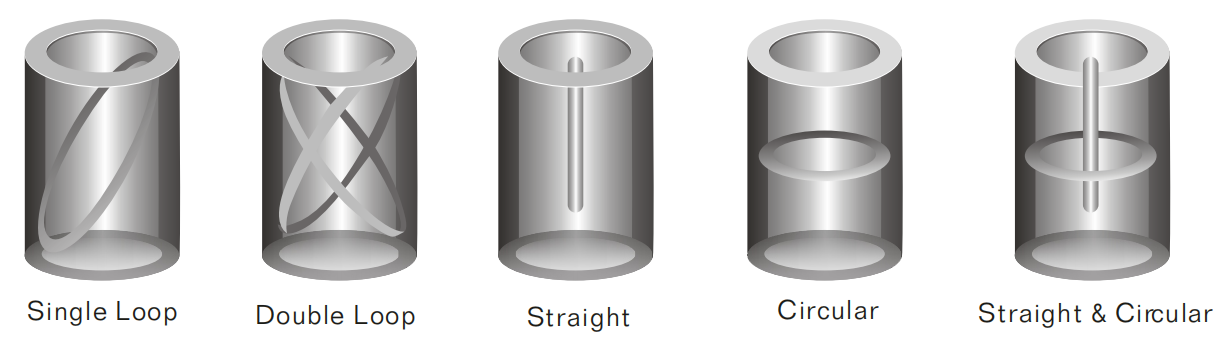

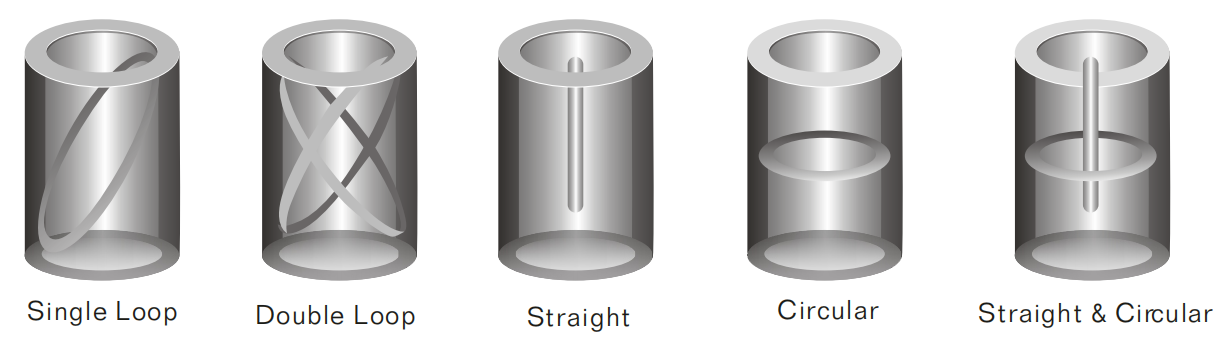

Patterns of lubrication groovesPopular lubrication grooves as shown below. Custom groove patterns can be made as per specific technical drawings.

Product Features

Product Features-Suitable for low speed, medium to high load applications.

-Excellent corrosion resistance and chemical resistance.

-Excellent wear resistance in lubricated operation.

-Resistant to impact load and vibration.

-Can be effectively compatible to foreign substance.

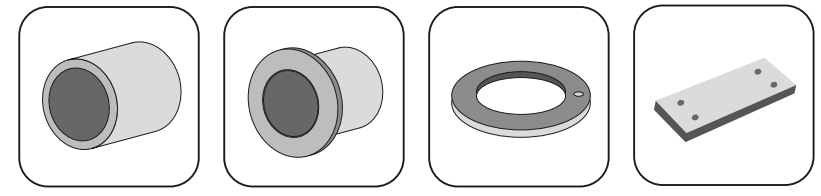

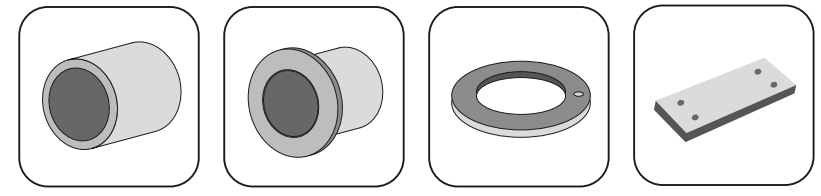

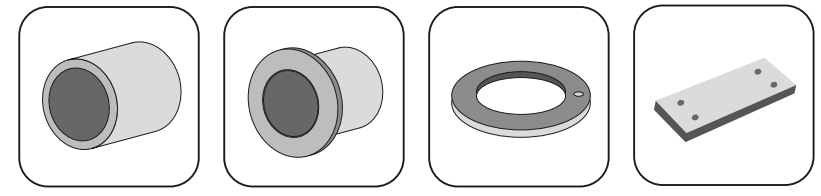

Available shapesRegular shapes are as shown below. Custom shapes are made on request.

Typical Applications

Typical ApplicationsPress machine, punching machine, forging machine,die and mold, mining machinery,agriculture machinery,metallurgy machinery,construction machinery, engineering machinery, etc.

In the electrolytic cell filled with electrolyte into the direct current, water molecules in the electrode electrochemical reaction, can be decomposed into hydrogen and oxygen, the whole process can achieve zero emissions. In the whole manufacturing process, the core equipment carrier is the electrolytic cell. Usually, the structure of the electrolytic cell is composed of three parts, namely, the tank body, the anode and the cathode. When direct current passes through the electrolytic cell, an oxidation reaction occurs at the interface between the anode and the solution, and a reduction reaction occurs at the interface between the cathode and the solution. At present, China's electrolytic water hydrogen production equipment is mostly used in photovoltaic, wind power, renewable energy hydrogen production is the main direction.

MCB

Multi-line text content element

HTML language content can be parsed after rich text content is bound to data

Classification:

Products

Metal Bearings

Key words: Electrolyzed water equipment

- DESCRIPTION

-

Product Introduction

MCB bearings are typical metallic bearings, designed for boundary lubrication operation.They are made of cast copper alloys.The alloy types are same with the ones of GCB. The difference is that no solid lubricants are inlaid into their bodies. To make the bushings well lubricated during operation,they are usually machined to have specific lubrication grooves at their inner surfaces. MCB bearings have excellent corrosion resistance and thermal conductivity. They are suitable for low speed, middle to high load applications. Under lubricated condition, they can perform very well due to the high strength and excellent lubricity of copper alloy.

Copper alloys and propertiesProduct Type

MCB63

MCB85

MCB80

MCB88

Alloy designation

CuZn25AI5Mn4Fe3

CuSn5Pb5Zn5

CuAl10Ni5Fe5

CuSn12

Density(g/cm³)

7.9

8.9

7.8

8.9

Hardness(HB)

≥210

≥70

≥150

≥75

Tensile Strength(MPa)

≥755

≥250

≥500

≥270

Yield Strength (MPa)

≥450

≥90

≥260

≥150

Elongation at break( %)

≥12

≥13

≥10

≥5

Thermal Expansion Coefficient

1.9x10*%/°C

1.8x10*9/°C

1.6x10^*/°C

1.8x10*/°C

Temperature range

-40~+300°C

-40~+400°C

-40~+400°C

-40~+400°C

Max. load (MPa)

100

50

50

50

Max.speed(m/s)

Dry

0.5

0.5

0.5

0.5

Lubricated

1

2.5

2.5

2.5

Max. PV (N/mm²*m/s)

Dry

1.65

1

1

1

Lubricated

3.25

1.65

1.65

1.65

Note: more copper alloys are made on request.

Patterns of lubrication groovesPopular lubrication grooves as shown below. Custom groove patterns can be made as per specific technical drawings.

Product Features

Product Features-Suitable for low speed, medium to high load applications.

-Excellent corrosion resistance and chemical resistance.

-Excellent wear resistance in lubricated operation.

-Resistant to impact load and vibration.

-Can be effectively compatible to foreign substance.

Available shapesRegular shapes are as shown below. Custom shapes are made on request.

Typical Applications

Typical ApplicationsPress machine, punching machine, forging machine,die and mold, mining machinery,agriculture machinery,metallurgy machinery,construction machinery, engineering machinery, etc.

In the electrolytic cell filled with electrolyte into the direct current, water molecules in the electrode electrochemical reaction, can be decomposed into hydrogen and oxygen, the whole process can achieve zero emissions. In the whole manufacturing process, the core equipment carrier is the electrolytic cell. Usually, the structure of the electrolytic cell is composed of three parts, namely, the tank body, the anode and the cathode. When direct current passes through the electrolytic cell, an oxidation reaction occurs at the interface between the anode and the solution, and a reduction reaction occurs at the interface between the cathode and the solution. At present, China's electrolytic water hydrogen production equipment is mostly used in photovoltaic, wind power, renewable energy hydrogen production is the main direction.

ORDER ONLINE

Filling in your phone and email information will help us to contact you in a timely manner and resolve your issue as soon as possible.

- DESCRIPTION

-

Product Introduction

MCB bearings are typical metallic bearings, designed for boundary lubrication operation.They are made of cast copper alloys.The alloy types are same with the ones of GCB. The difference is that no solid lubricants are inlaid into their bodies. To make the bushings well lubricated during operation,they are usually machined to have specific lubrication grooves at their inner surfaces. MCB bearings have excellent corrosion resistance and thermal conductivity. They are suitable for low speed, middle to high load applications. Under lubricated condition, they can perform very well due to the high strength and excellent lubricity of copper alloy.

Copper alloys and propertiesProduct Type

MCB63

MCB85

MCB80

MCB88

Alloy designation

CuZn25AI5Mn4Fe3

CuSn5Pb5Zn5

CuAl10Ni5Fe5

CuSn12

Density(g/cm³)

7.9

8.9

7.8

8.9

Hardness(HB)

≥210

≥70

≥150

≥75

Tensile Strength(MPa)

≥755

≥250

≥500

≥270

Yield Strength (MPa)

≥450

≥90

≥260

≥150

Elongation at break( %)

≥12

≥13

≥10

≥5

Thermal Expansion Coefficient

1.9x10*%/°C

1.8x10*9/°C

1.6x10^*/°C

1.8x10*/°C

Temperature range

-40~+300°C

-40~+400°C

-40~+400°C

-40~+400°C

Max. load (MPa)

100

50

50

50

Max.speed(m/s)

Dry

0.5

0.5

0.5

0.5

Lubricated

1

2.5

2.5

2.5

Max. PV (N/mm²*m/s)

Dry

1.65

1

1

1

Lubricated

3.25

1.65

1.65

1.65

Note: more copper alloys are made on request.

Patterns of lubrication groovesPopular lubrication grooves as shown below. Custom groove patterns can be made as per specific technical drawings.

Product Features

Product Features-Suitable for low speed, medium to high load applications.

-Excellent corrosion resistance and chemical resistance.

-Excellent wear resistance in lubricated operation.

-Resistant to impact load and vibration.

-Can be effectively compatible to foreign substance.

Available shapesRegular shapes are as shown below. Custom shapes are made on request.

Typical Applications

Typical ApplicationsPress machine, punching machine, forging machine,die and mold, mining machinery,agriculture machinery,metallurgy machinery,construction machinery, engineering machinery, etc.

In the electrolytic cell filled with electrolyte into the direct current, water molecules in the electrode electrochemical reaction, can be decomposed into hydrogen and oxygen, the whole process can achieve zero emissions. In the whole manufacturing process, the core equipment carrier is the electrolytic cell. Usually, the structure of the electrolytic cell is composed of three parts, namely, the tank body, the anode and the cathode. When direct current passes through the electrolytic cell, an oxidation reaction occurs at the interface between the anode and the solution, and a reduction reaction occurs at the interface between the cathode and the solution. At present, China's electrolytic water hydrogen production equipment is mostly used in photovoltaic, wind power, renewable energy hydrogen production is the main direction.