Hot Products For All Applications

WB09

Multi-line text content element

HTML language content can be parsed after rich text content is bound to data

Classification:

Products

Metal Bearings

Key words: Electrolyzed water equipment

- DESCRIPTION

-

Product introduction

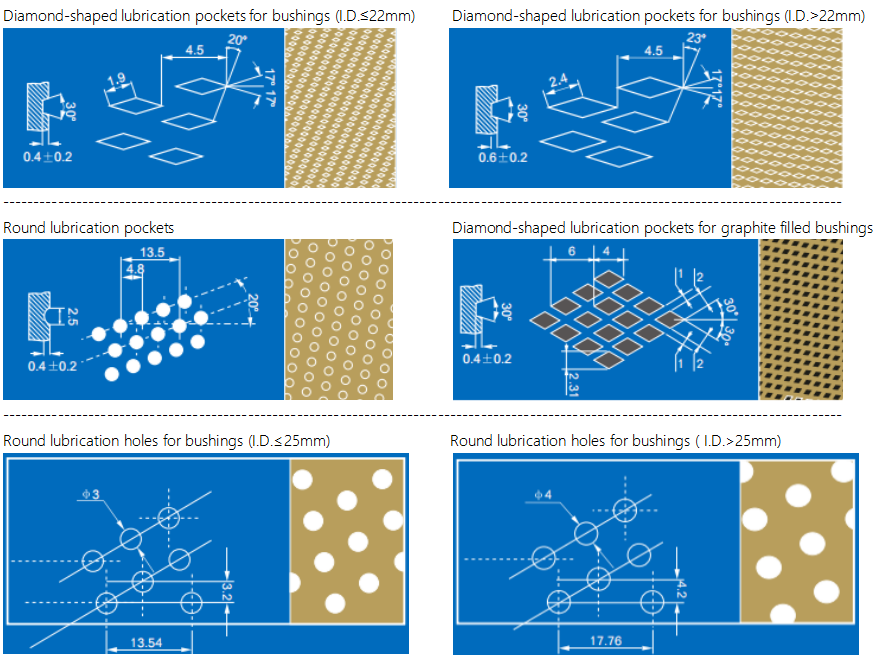

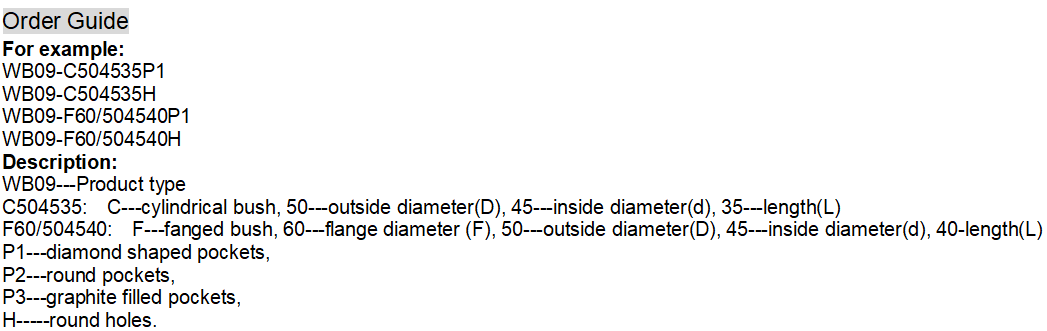

WB09 bearings are made of bronze strips. This bearing material is featured with excellent corrosion resistance, good lubricity, low friction, high wear resistance, high thermal conductivity. And also it has good toughness and fatigue resistance. In order to make it get fully lubricated, lubrication pockets or holes are specially designed. Lubrication grooves are available as well according to specific requirement. If for dry operation, the lubrication pockets can be filled with solid lubricants such as graphite.

Available copper alloyCuSn8P0.3

(Note: CuSn8P0.3 is the recommended material. Other copper alloys are negotiable. )

PropertiesParameter

Value

Max. load

120N/mm²Static

40N/mm²Dynamic

Max.sliding speed

2m/s(Lubricated)

Max. PV

2.8N/mm²*m/s(Lubricated)

Coefficient of friction

0.08~0.25(Lubricated)

Density

8.8g/cm3

Alloy hardness

HB90-150

Temperature range

-80℃~+200℃

Thermal conductivity

58W(m*K)-18

Coefficient of linear thermal expansion

18.5*10-6*K-1

Product features-Good fatigue resistance.

-Good wear resistance and anti-corrosion.

-Excellent performance in fluid and boundary lubrication operation.

-Suitable for low to Middle load and low speed use

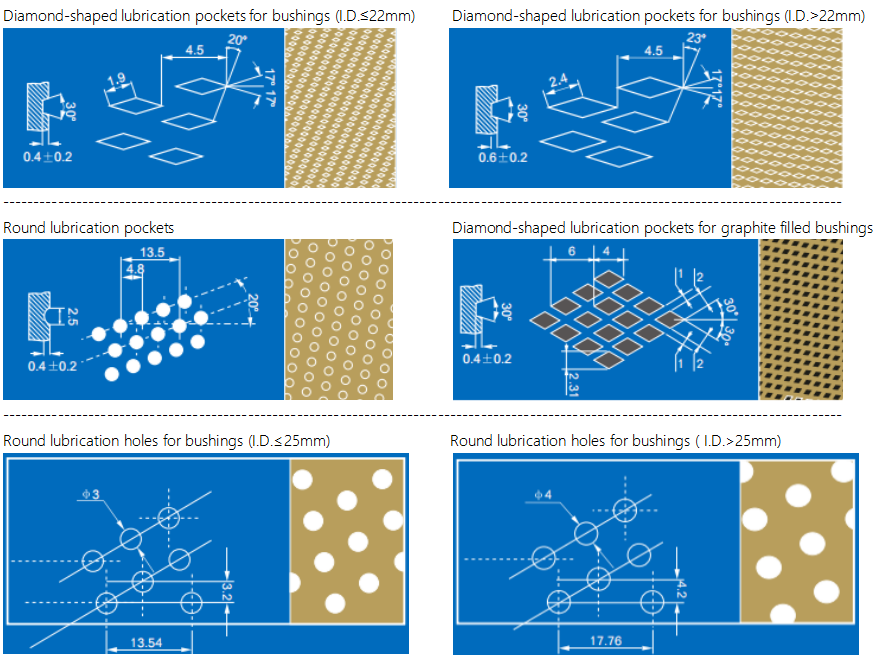

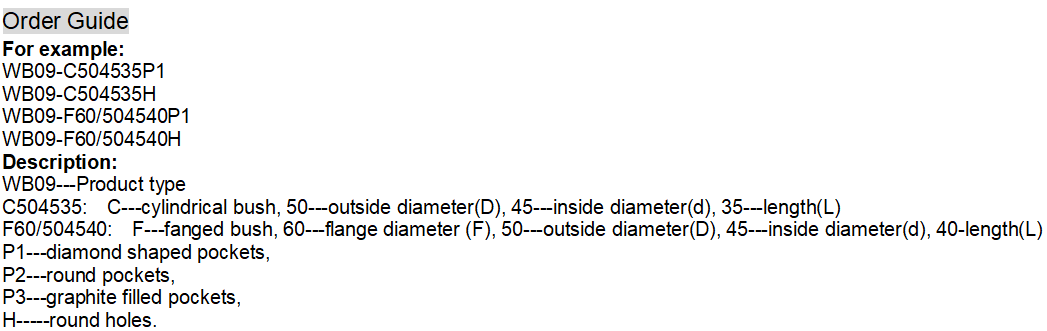

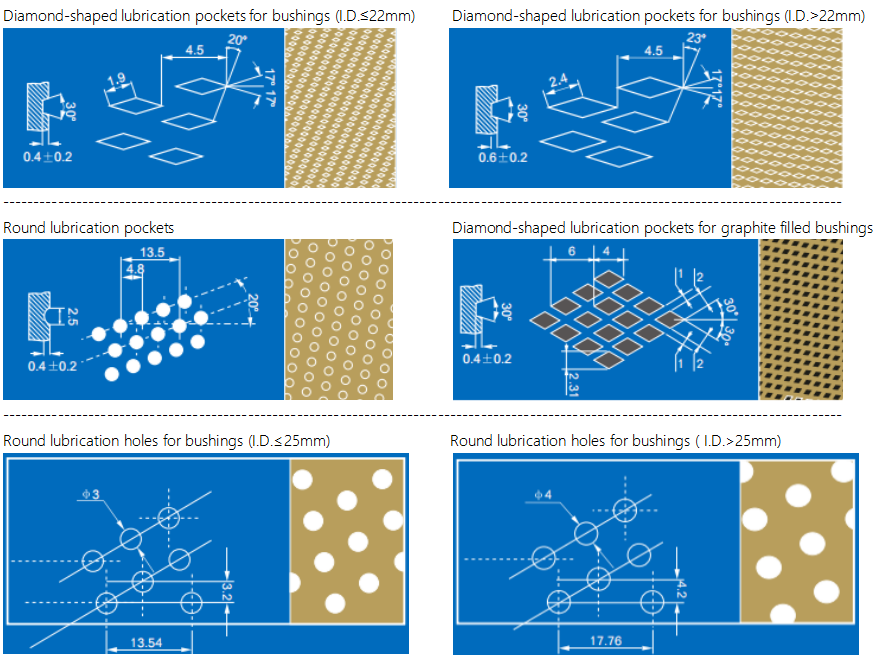

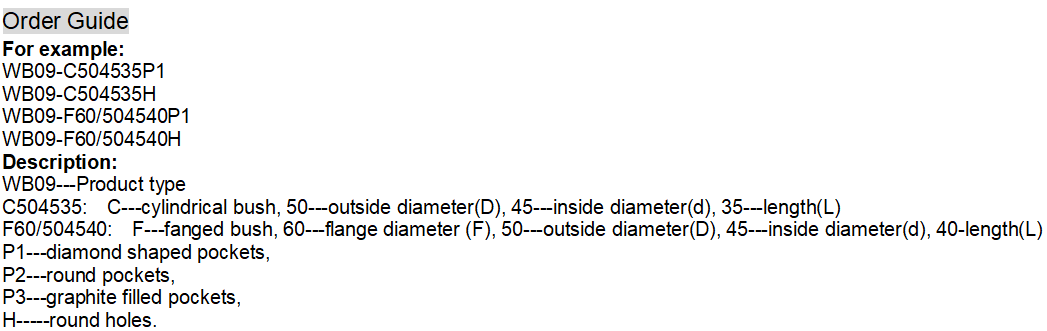

Lubrication pockets or holes Available product shapes

Available product shapesRegular shapes include cylindrical bush,flanged bush,thrust washer.For standard sizes, please check out size table. Custom shapes can be made on request.

Typical applications

Typical applicationsLifting machinery, construction machinery, automotive tractor chassis, machine tool industry, and mining machinery.

In the electrolytic cell filled with electrolyte into the direct current, water molecules in the electrode electrochemical reaction, can be decomposed into hydrogen and oxygen, the whole process can achieve zero emissions. In the whole manufacturing process, the core equipment carrier is the electrolytic cell. Usually, the structure of the electrolytic cell is composed of three parts, namely, the tank body, the anode and the cathode. When direct current passes through the electrolytic cell, an oxidation reaction occurs at the interface between the anode and the solution, and a reduction reaction occurs at the interface between the cathode and the solution. At present, China's electrolytic water hydrogen production equipment is mostly used in photovoltaic, wind power, renewable energy hydrogen production is the main direction.

WB09

Multi-line text content element

HTML language content can be parsed after rich text content is bound to data

Classification:

Products

Metal Bearings

Key words: Electrolyzed water equipment

- DESCRIPTION

-

Product introduction

WB09 bearings are made of bronze strips. This bearing material is featured with excellent corrosion resistance, good lubricity, low friction, high wear resistance, high thermal conductivity. And also it has good toughness and fatigue resistance. In order to make it get fully lubricated, lubrication pockets or holes are specially designed. Lubrication grooves are available as well according to specific requirement. If for dry operation, the lubrication pockets can be filled with solid lubricants such as graphite.

Available copper alloyCuSn8P0.3

(Note: CuSn8P0.3 is the recommended material. Other copper alloys are negotiable. )

PropertiesParameter

Value

Max. load

120N/mm²Static

40N/mm²Dynamic

Max.sliding speed

2m/s(Lubricated)

Max. PV

2.8N/mm²*m/s(Lubricated)

Coefficient of friction

0.08~0.25(Lubricated)

Density

8.8g/cm3

Alloy hardness

HB90-150

Temperature range

-80℃~+200℃

Thermal conductivity

58W(m*K)-18

Coefficient of linear thermal expansion

18.5*10-6*K-1

Product features-Good fatigue resistance.

-Good wear resistance and anti-corrosion.

-Excellent performance in fluid and boundary lubrication operation.

-Suitable for low to Middle load and low speed use

Lubrication pockets or holes Available product shapes

Available product shapesRegular shapes include cylindrical bush,flanged bush,thrust washer.For standard sizes, please check out size table. Custom shapes can be made on request.

Typical applications

Typical applicationsLifting machinery, construction machinery, automotive tractor chassis, machine tool industry, and mining machinery.

In the electrolytic cell filled with electrolyte into the direct current, water molecules in the electrode electrochemical reaction, can be decomposed into hydrogen and oxygen, the whole process can achieve zero emissions. In the whole manufacturing process, the core equipment carrier is the electrolytic cell. Usually, the structure of the electrolytic cell is composed of three parts, namely, the tank body, the anode and the cathode. When direct current passes through the electrolytic cell, an oxidation reaction occurs at the interface between the anode and the solution, and a reduction reaction occurs at the interface between the cathode and the solution. At present, China's electrolytic water hydrogen production equipment is mostly used in photovoltaic, wind power, renewable energy hydrogen production is the main direction.

ORDER ONLINE

Filling in your phone and email information will help us to contact you in a timely manner and resolve your issue as soon as possible.

- DESCRIPTION

-

Product introduction

WB09 bearings are made of bronze strips. This bearing material is featured with excellent corrosion resistance, good lubricity, low friction, high wear resistance, high thermal conductivity. And also it has good toughness and fatigue resistance. In order to make it get fully lubricated, lubrication pockets or holes are specially designed. Lubrication grooves are available as well according to specific requirement. If for dry operation, the lubrication pockets can be filled with solid lubricants such as graphite.

Available copper alloyCuSn8P0.3

(Note: CuSn8P0.3 is the recommended material. Other copper alloys are negotiable. )

PropertiesParameter

Value

Max. load

120N/mm²Static

40N/mm²Dynamic

Max.sliding speed

2m/s(Lubricated)

Max. PV

2.8N/mm²*m/s(Lubricated)

Coefficient of friction

0.08~0.25(Lubricated)

Density

8.8g/cm3

Alloy hardness

HB90-150

Temperature range

-80℃~+200℃

Thermal conductivity

58W(m*K)-18

Coefficient of linear thermal expansion

18.5*10-6*K-1

Product features-Good fatigue resistance.

-Good wear resistance and anti-corrosion.

-Excellent performance in fluid and boundary lubrication operation.

-Suitable for low to Middle load and low speed use

Lubrication pockets or holes Available product shapes

Available product shapesRegular shapes include cylindrical bush,flanged bush,thrust washer.For standard sizes, please check out size table. Custom shapes can be made on request.

Typical applications

Typical applicationsLifting machinery, construction machinery, automotive tractor chassis, machine tool industry, and mining machinery.

In the electrolytic cell filled with electrolyte into the direct current, water molecules in the electrode electrochemical reaction, can be decomposed into hydrogen and oxygen, the whole process can achieve zero emissions. In the whole manufacturing process, the core equipment carrier is the electrolytic cell. Usually, the structure of the electrolytic cell is composed of three parts, namely, the tank body, the anode and the cathode. When direct current passes through the electrolytic cell, an oxidation reaction occurs at the interface between the anode and the solution, and a reduction reaction occurs at the interface between the cathode and the solution. At present, China's electrolytic water hydrogen production equipment is mostly used in photovoltaic, wind power, renewable energy hydrogen production is the main direction.