Hot Products For All Applications

BIM

Multi-line text content element

HTML language content can be parsed after rich text content is bound to data

Classification:

Products

Metal Bearings

Key words: Electrolyzed water equipment

- DESCRIPTION

-

Product introduction

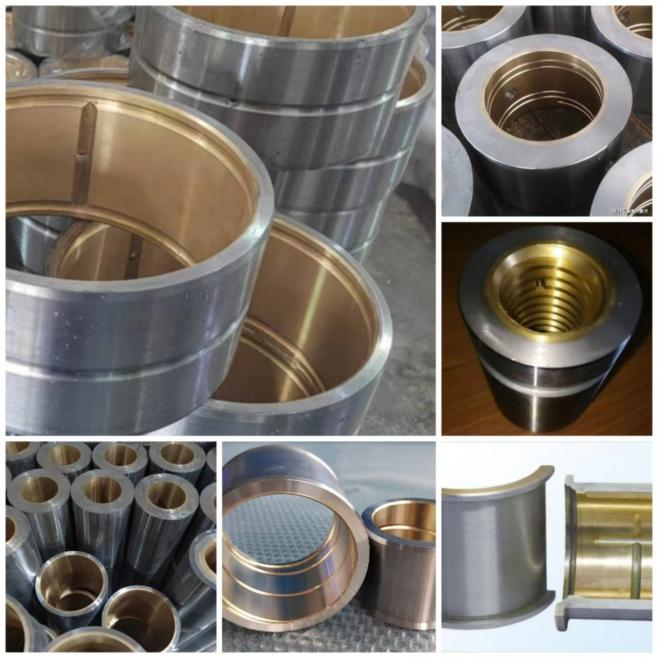

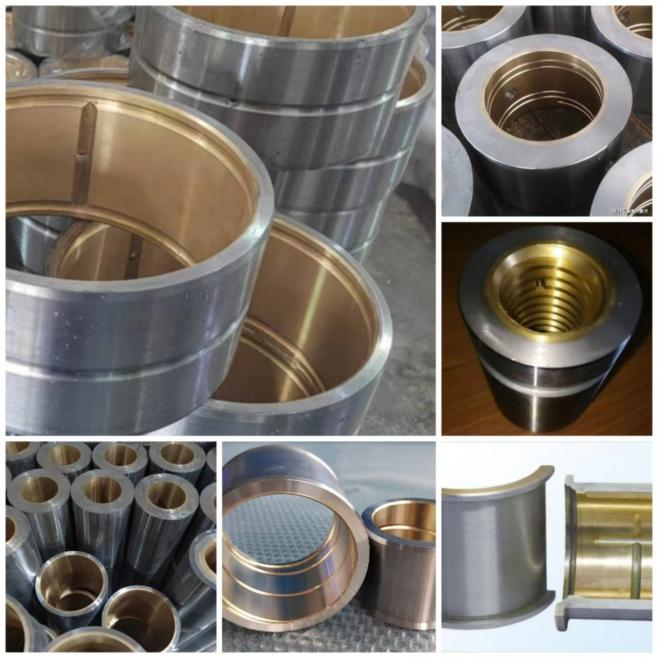

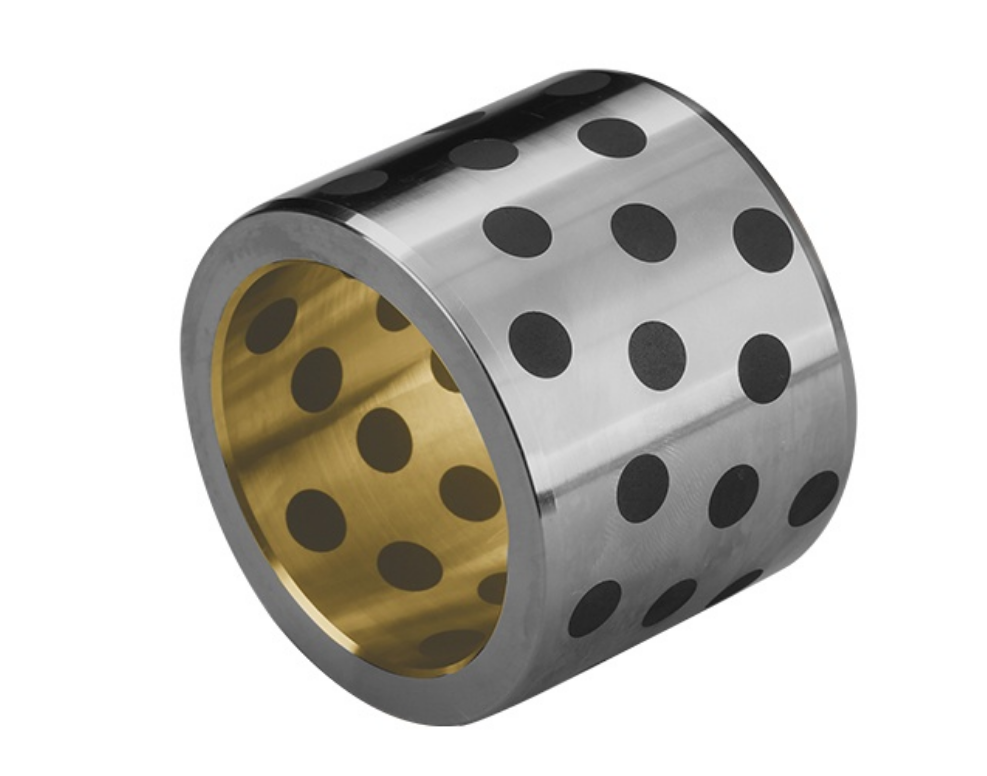

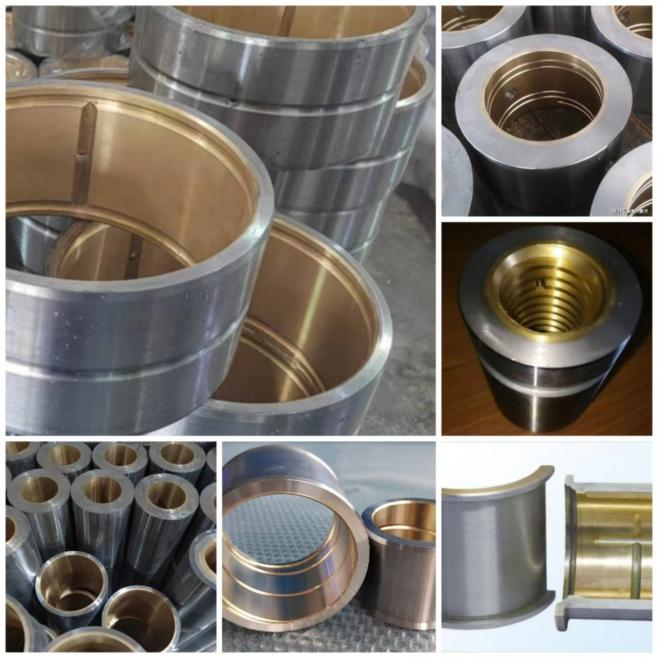

BIM bimetal bearing material generally consists of a layer of steel backing and a layer of alloy lining. It’s a typical composite bearing material, widely used in a variety of industries. The steel backing can provide powerful supporting strength, sustaining the stability for the bearing size. The alloy lining serves as sliding element due to its excellent lubricity and excellent wear resistance property. Bronze alloys are most often used as the lining materials. Other metal alloys can be used in some cases as well.

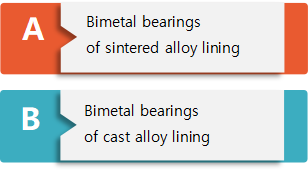

Basically, we can supply two different categories of bimetal bearings by employing two different methods of production, as shown below:

Bimetal bearings of sintered alloy lining( Technique-A)

Bimetal bearings of sintered alloy lining( Technique-A)Just as its name implies, this kind of bimetal bearing material has a layer of sintered alloy as its lining. That's to say, the lining of this kind of bimetal bearing material is normally sintered onto the steel backing in high temperature furnace. By this method, bimetallic plates or strips are firstly manufactured before processed into bushings or thrust washers. The alloy lining is often rolled or machined to have plenty of regularly arranged lubrication pockets or specific grooves so as to make the bearings get fully lubricated during operation.

BIM80,BIM90,BIM87,BIM85,BIM20 are typical bimetal bearing materials of sintered alloy lining.The backing material for them are high performance mild steel. There are five types of alloy used as the lining material for them respectively. Relevant products and their properties are shown as below.

Bimetal bearings of cast alloy lining(Technique-B)BIM45, BIM45G,BIM45H are typical bimetal bearing materials having cast alloy lining.The backing material is normally made of high performance seamless medium carbon steel pipe.The most often used alloy lining materials are as follows. Custom alloy can be supplied on request. Due to the unique production method, heavy-walled or big size bimetal bearings can be produced as per specific technical drawings.

1.CuSn10Pb1

2.CuSn5Pb5Zn5

3.CuSn12

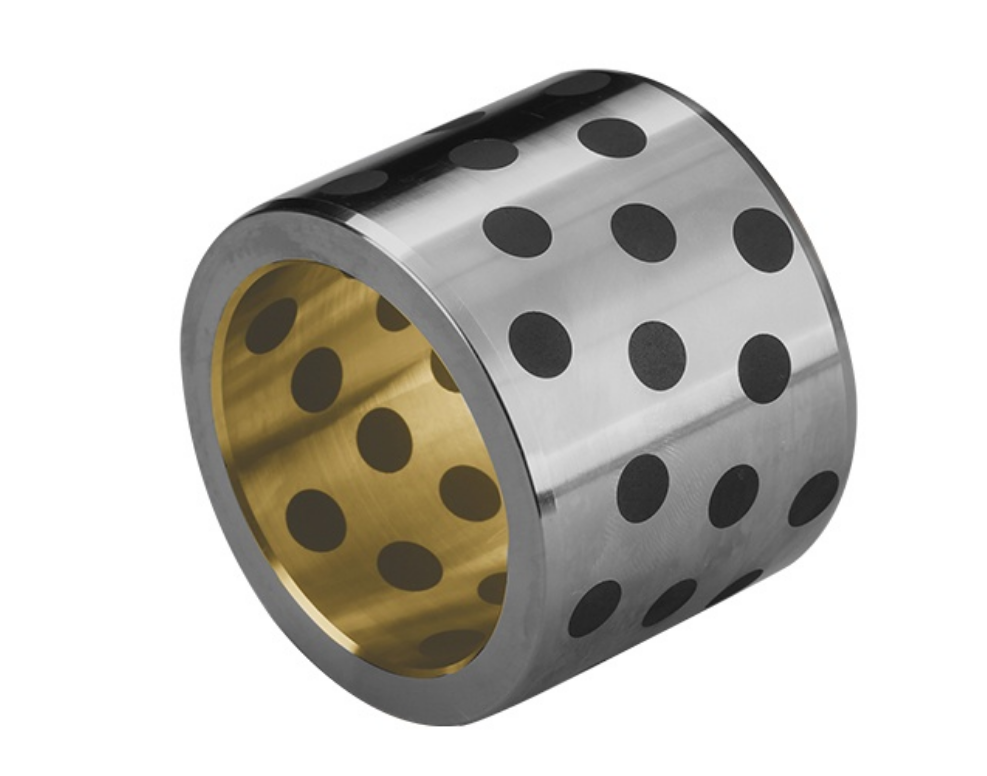

4.CuZn25Al6Fe3Mn3BIM45------Machined grooves for lubricated operation.

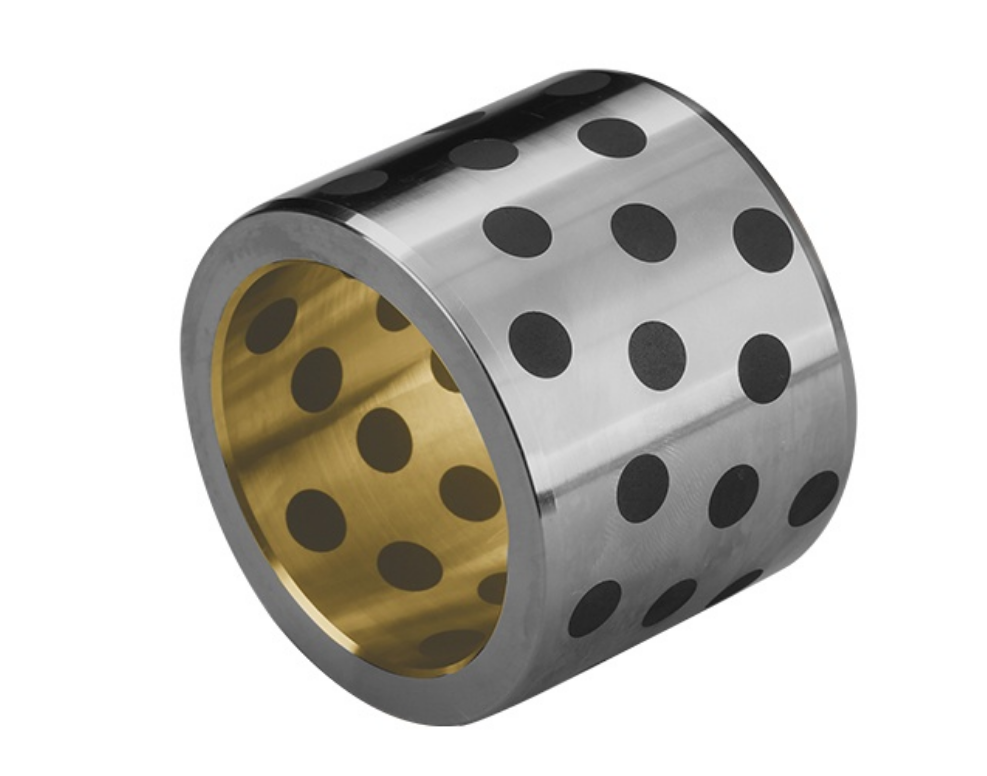

BIM45G-----Solid lubricants are filled in the pockets of inner surfaces, can be used in dry operation condition.

BIM45H-----Solid lubricants are inserted in the holes of its body, same with the design of GCB, for dry operation. The raw material cost of BIM45H is less than that of GCB. In some cases, BIM45H can be a low cost replacement solution for GCB.

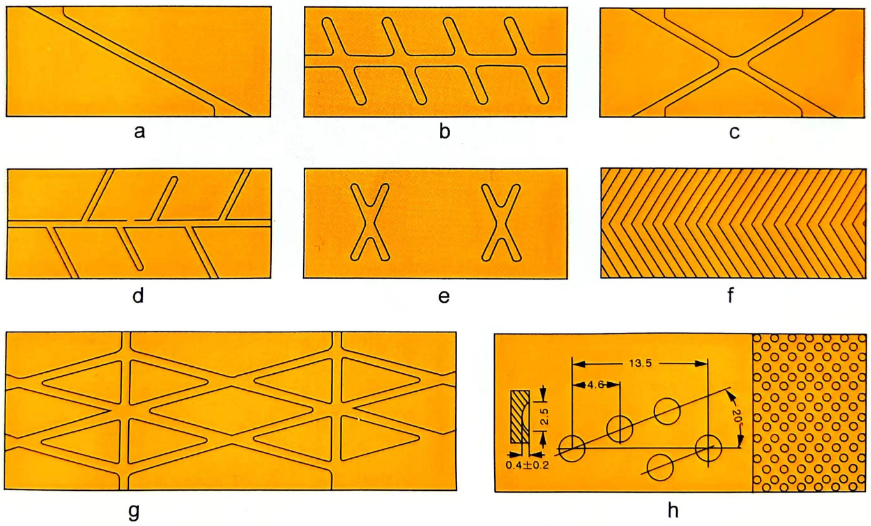

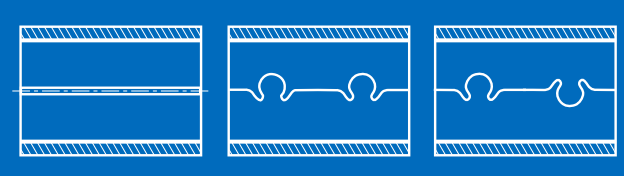

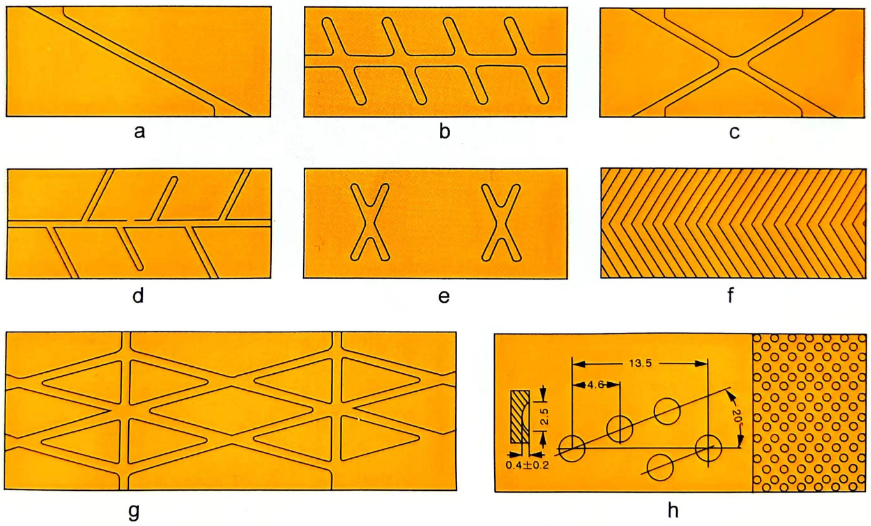

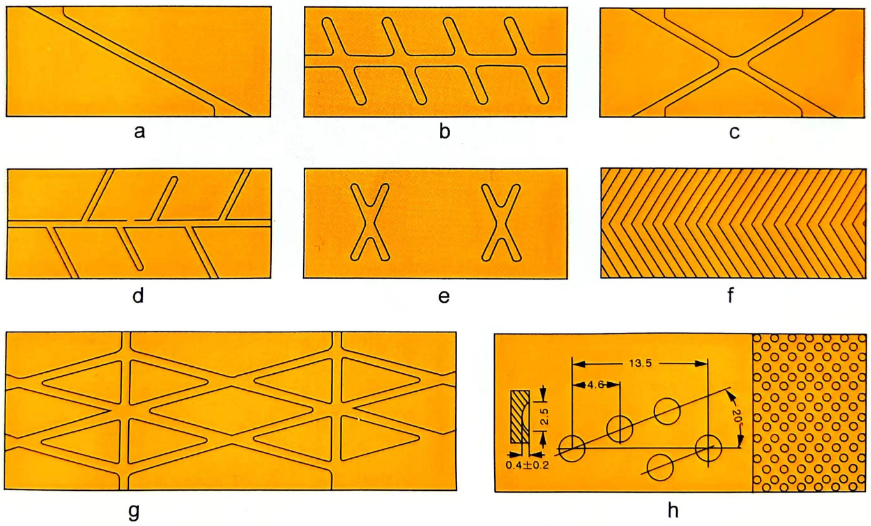

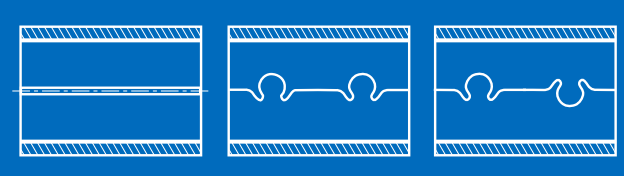

Recommended patterns of grooves and pockets for wrapped bimetal bushings.

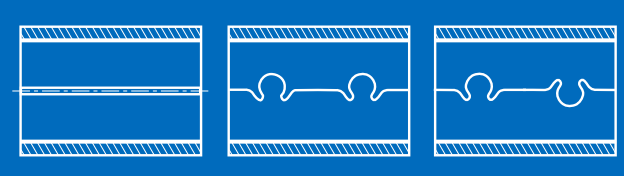

Recommended patterns of grooves and pockets for wrapped bimetal bushings. Type of joints for wrapped bimetal bearings

Type of joints for wrapped bimetal bearings Recommended sizes for lubricating holesProduct features

Recommended sizes for lubricating holesProduct features-Good wear resistance

-Resistant to high temperature

-Suitable for middle to high loads.

-Excellent fatigue resistance under dynamic and shock load operation.

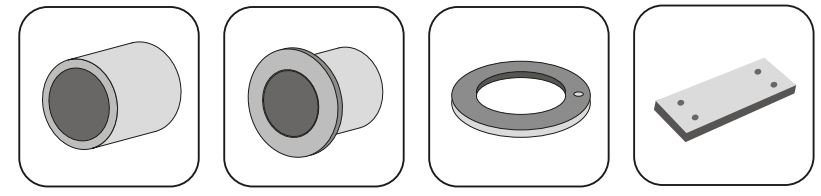

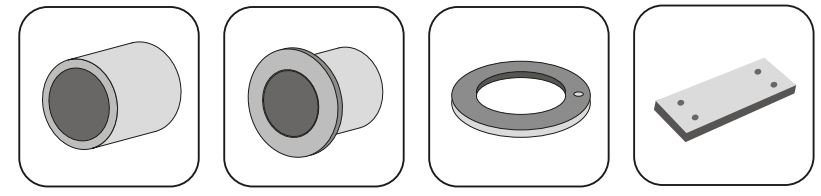

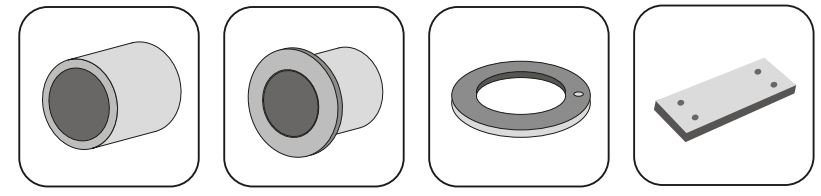

Available product shapesCylindrical bush, flanged bush, thrust washer and sliding plate.

Custom shapes are made on request.

Typical applications-General industry

Engineering machinery, construction machinery,agriculture machinery,lifting equipment,pneumatic equipment, plunger pump,hydraulic cylinder,mould and die, punch press,etc.

-Vehicle

Trunnion bushing, leaf spring bushing, camshaft bushing,crankshaft bushing , connecting rod bushing,valve rocker arm bushing,king pin bushing of steering knuckle, side plate,etc.

In the electrolytic cell filled with electrolyte into the direct current, water molecules in the electrode electrochemical reaction, can be decomposed into hydrogen and oxygen, the whole process can achieve zero emissions. In the whole manufacturing process, the core equipment carrier is the electrolytic cell. Usually, the structure of the electrolytic cell is composed of three parts, namely, the tank body, the anode and the cathode. When direct current passes through the electrolytic cell, an oxidation reaction occurs at the interface between the anode and the solution, and a reduction reaction occurs at the interface between the cathode and the solution. At present, China's electrolytic water hydrogen production equipment is mostly used in photovoltaic, wind power, renewable energy hydrogen production is the main direction.

BIM

Multi-line text content element

HTML language content can be parsed after rich text content is bound to data

Classification:

Products

Metal Bearings

Key words: Electrolyzed water equipment

- DESCRIPTION

-

Product introduction

BIM bimetal bearing material generally consists of a layer of steel backing and a layer of alloy lining. It’s a typical composite bearing material, widely used in a variety of industries. The steel backing can provide powerful supporting strength, sustaining the stability for the bearing size. The alloy lining serves as sliding element due to its excellent lubricity and excellent wear resistance property. Bronze alloys are most often used as the lining materials. Other metal alloys can be used in some cases as well.

Basically, we can supply two different categories of bimetal bearings by employing two different methods of production, as shown below:

Bimetal bearings of sintered alloy lining( Technique-A)

Bimetal bearings of sintered alloy lining( Technique-A)Just as its name implies, this kind of bimetal bearing material has a layer of sintered alloy as its lining. That's to say, the lining of this kind of bimetal bearing material is normally sintered onto the steel backing in high temperature furnace. By this method, bimetallic plates or strips are firstly manufactured before processed into bushings or thrust washers. The alloy lining is often rolled or machined to have plenty of regularly arranged lubrication pockets or specific grooves so as to make the bearings get fully lubricated during operation.

BIM80,BIM90,BIM87,BIM85,BIM20 are typical bimetal bearing materials of sintered alloy lining.The backing material for them are high performance mild steel. There are five types of alloy used as the lining material for them respectively. Relevant products and their properties are shown as below.

Bimetal bearings of cast alloy lining(Technique-B)BIM45, BIM45G,BIM45H are typical bimetal bearing materials having cast alloy lining.The backing material is normally made of high performance seamless medium carbon steel pipe.The most often used alloy lining materials are as follows. Custom alloy can be supplied on request. Due to the unique production method, heavy-walled or big size bimetal bearings can be produced as per specific technical drawings.

1.CuSn10Pb1

2.CuSn5Pb5Zn5

3.CuSn12

4.CuZn25Al6Fe3Mn3BIM45------Machined grooves for lubricated operation.

BIM45G-----Solid lubricants are filled in the pockets of inner surfaces, can be used in dry operation condition.

BIM45H-----Solid lubricants are inserted in the holes of its body, same with the design of GCB, for dry operation. The raw material cost of BIM45H is less than that of GCB. In some cases, BIM45H can be a low cost replacement solution for GCB.

Recommended patterns of grooves and pockets for wrapped bimetal bushings.

Recommended patterns of grooves and pockets for wrapped bimetal bushings. Type of joints for wrapped bimetal bearings

Type of joints for wrapped bimetal bearings Recommended sizes for lubricating holesProduct features

Recommended sizes for lubricating holesProduct features-Good wear resistance

-Resistant to high temperature

-Suitable for middle to high loads.

-Excellent fatigue resistance under dynamic and shock load operation.

Available product shapesCylindrical bush, flanged bush, thrust washer and sliding plate.

Custom shapes are made on request.

Typical applications-General industry

Engineering machinery, construction machinery,agriculture machinery,lifting equipment,pneumatic equipment, plunger pump,hydraulic cylinder,mould and die, punch press,etc.

-Vehicle

Trunnion bushing, leaf spring bushing, camshaft bushing,crankshaft bushing , connecting rod bushing,valve rocker arm bushing,king pin bushing of steering knuckle, side plate,etc.

In the electrolytic cell filled with electrolyte into the direct current, water molecules in the electrode electrochemical reaction, can be decomposed into hydrogen and oxygen, the whole process can achieve zero emissions. In the whole manufacturing process, the core equipment carrier is the electrolytic cell. Usually, the structure of the electrolytic cell is composed of three parts, namely, the tank body, the anode and the cathode. When direct current passes through the electrolytic cell, an oxidation reaction occurs at the interface between the anode and the solution, and a reduction reaction occurs at the interface between the cathode and the solution. At present, China's electrolytic water hydrogen production equipment is mostly used in photovoltaic, wind power, renewable energy hydrogen production is the main direction.

ORDER ONLINE

Filling in your phone and email information will help us to contact you in a timely manner and resolve your issue as soon as possible.

- DESCRIPTION

-

Product introduction

BIM bimetal bearing material generally consists of a layer of steel backing and a layer of alloy lining. It’s a typical composite bearing material, widely used in a variety of industries. The steel backing can provide powerful supporting strength, sustaining the stability for the bearing size. The alloy lining serves as sliding element due to its excellent lubricity and excellent wear resistance property. Bronze alloys are most often used as the lining materials. Other metal alloys can be used in some cases as well.

Basically, we can supply two different categories of bimetal bearings by employing two different methods of production, as shown below:

Bimetal bearings of sintered alloy lining( Technique-A)

Bimetal bearings of sintered alloy lining( Technique-A)Just as its name implies, this kind of bimetal bearing material has a layer of sintered alloy as its lining. That's to say, the lining of this kind of bimetal bearing material is normally sintered onto the steel backing in high temperature furnace. By this method, bimetallic plates or strips are firstly manufactured before processed into bushings or thrust washers. The alloy lining is often rolled or machined to have plenty of regularly arranged lubrication pockets or specific grooves so as to make the bearings get fully lubricated during operation.

BIM80,BIM90,BIM87,BIM85,BIM20 are typical bimetal bearing materials of sintered alloy lining.The backing material for them are high performance mild steel. There are five types of alloy used as the lining material for them respectively. Relevant products and their properties are shown as below.

Bimetal bearings of cast alloy lining(Technique-B)BIM45, BIM45G,BIM45H are typical bimetal bearing materials having cast alloy lining.The backing material is normally made of high performance seamless medium carbon steel pipe.The most often used alloy lining materials are as follows. Custom alloy can be supplied on request. Due to the unique production method, heavy-walled or big size bimetal bearings can be produced as per specific technical drawings.

1.CuSn10Pb1

2.CuSn5Pb5Zn5

3.CuSn12

4.CuZn25Al6Fe3Mn3BIM45------Machined grooves for lubricated operation.

BIM45G-----Solid lubricants are filled in the pockets of inner surfaces, can be used in dry operation condition.

BIM45H-----Solid lubricants are inserted in the holes of its body, same with the design of GCB, for dry operation. The raw material cost of BIM45H is less than that of GCB. In some cases, BIM45H can be a low cost replacement solution for GCB.

Recommended patterns of grooves and pockets for wrapped bimetal bushings.

Recommended patterns of grooves and pockets for wrapped bimetal bushings. Type of joints for wrapped bimetal bearings

Type of joints for wrapped bimetal bearings Recommended sizes for lubricating holesProduct features

Recommended sizes for lubricating holesProduct features-Good wear resistance

-Resistant to high temperature

-Suitable for middle to high loads.

-Excellent fatigue resistance under dynamic and shock load operation.

Available product shapesCylindrical bush, flanged bush, thrust washer and sliding plate.

Custom shapes are made on request.

Typical applications-General industry

Engineering machinery, construction machinery,agriculture machinery,lifting equipment,pneumatic equipment, plunger pump,hydraulic cylinder,mould and die, punch press,etc.

-Vehicle

Trunnion bushing, leaf spring bushing, camshaft bushing,crankshaft bushing , connecting rod bushing,valve rocker arm bushing,king pin bushing of steering knuckle, side plate,etc.

In the electrolytic cell filled with electrolyte into the direct current, water molecules in the electrode electrochemical reaction, can be decomposed into hydrogen and oxygen, the whole process can achieve zero emissions. In the whole manufacturing process, the core equipment carrier is the electrolytic cell. Usually, the structure of the electrolytic cell is composed of three parts, namely, the tank body, the anode and the cathode. When direct current passes through the electrolytic cell, an oxidation reaction occurs at the interface between the anode and the solution, and a reduction reaction occurs at the interface between the cathode and the solution. At present, China's electrolytic water hydrogen production equipment is mostly used in photovoltaic, wind power, renewable energy hydrogen production is the main direction.