Hot Products For All Applications

FRC

Multi-line text content element

HTML language content can be parsed after rich text content is bound to data

Classification:

Products

Polymer Bearings

Key words: Electrolyzed water equipment

- DESCRIPTION

-

Product introduction

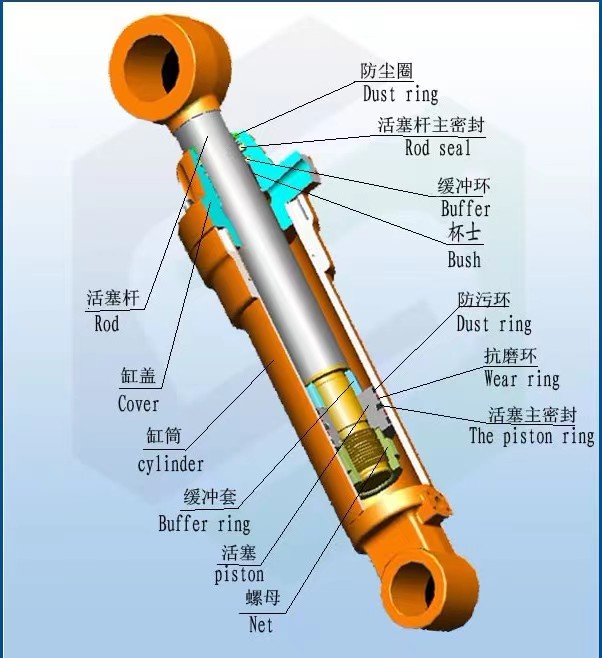

FRC is composed of thermosetting resin and high-strength fibers. The thermosetting resin provides strong support and dimensional stability for the composite. High-strength fibers serve as reinforcement material. FRC products are characterized by light weight,high load capacity, high wear resistance,very low friction, excellent corrosion resistance. They are particularly suitable for low speed, medium to high load applications.

FRC can be categorized into phenolic resin-based FRC and epoxy resin-based FRC. Both of them are produced by the technique of filament winding forming. By this method, continuous fiber filaments or cloth tapes are firstly impregnated with specific liquid resin and then wound onto a given mandrel to get the desired shape and wall thickness. After that, through high-temperature curing and demolding, semi-products can be obtained. Finished products of high precision can be availabe after CNC machining.

Phenolic resin-based FRC is a wear resistant material of single-layer structure. FRC1,FRC2,FRC3,FRC4 are typical phenolic resin-based products.They are often used as wear ring (guide ring, supporting ring) for pistons of hydraulic cylinders, or guide bush for pillars of hydraulic machinery. Epoxy resin-based FRC is a wear resistant material of two-layer structure . This category of material is commonly used as bushings or thrust washers in a variety of machinery or equipment. FRC5 is a typical epoxy resin-based product .

Phenolic resin based FRC

FRC1

Material composition: linear phenolic resin+cotton fiber fabric

FRC2

Material composition: soluble phenolic resin containing graphite+cotton fiber fabric

FRC3

Material composition: linear phenolic resin+polyester fiber fabric

FRC4

Material composition: soluble phenolic resin containing MoS2+carbon fiber fabric

Properties of FRC1/FRC2/FRC3/FRC4Note: more colors are available,depending upon the fillers.

Epoxy resin based FRCFRC5

Material structure and composition

Material structure and composition-lining layer

PTFE fiber filaments and polyester fiber filaments are continuously wound and encapsulated in high temperature solid lubricated-filled epoxy resin.

-backing layer

glass fiber filaments are continuously wound and encapsulated in high temperature epoxy resin.

Properties of FRC5Product features-Self-lubricating, maintenance-free.

-Good chemical resistance.

-High load carrying capacity.

-Low friction and high wear resistance.

-Excellent shock and misalignment resistance.

-Excellent contamination resistance.

Typical applicationshydraulic cylinders,engineering machinery,mining machinery, lifting equipment,etc.

In the electrolytic cell filled with electrolyte into the direct current, water molecules in the electrode electrochemical reaction, can be decomposed into hydrogen and oxygen, the whole process can achieve zero emissions. In the whole manufacturing process, the core equipment carrier is the electrolytic cell. Usually, the structure of the electrolytic cell is composed of three parts, namely, the tank body, the anode and the cathode. When direct current passes through the electrolytic cell, an oxidation reaction occurs at the interface between the anode and the solution, and a reduction reaction occurs at the interface between the cathode and the solution. At present, China's electrolytic water hydrogen production equipment is mostly used in photovoltaic, wind power, renewable energy hydrogen production is the main direction.

FRC

Multi-line text content element

HTML language content can be parsed after rich text content is bound to data

Classification:

Products

Polymer Bearings

Key words: Electrolyzed water equipment

- DESCRIPTION

-

Product introduction

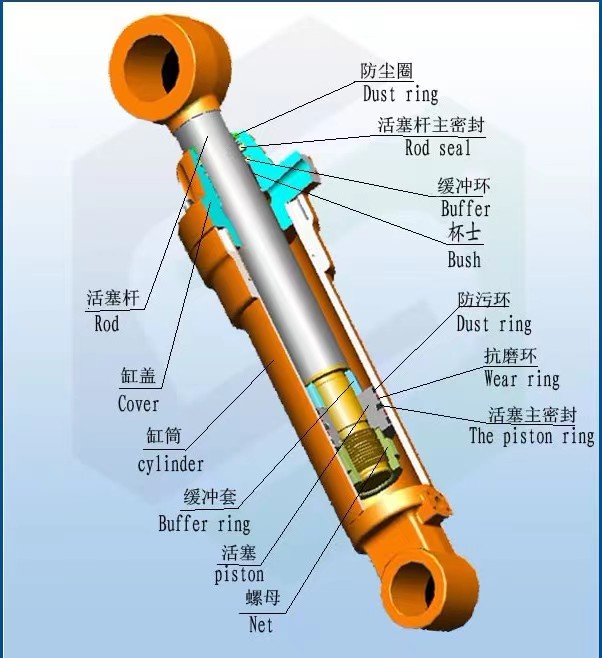

FRC is composed of thermosetting resin and high-strength fibers. The thermosetting resin provides strong support and dimensional stability for the composite. High-strength fibers serve as reinforcement material. FRC products are characterized by light weight,high load capacity, high wear resistance,very low friction, excellent corrosion resistance. They are particularly suitable for low speed, medium to high load applications.

FRC can be categorized into phenolic resin-based FRC and epoxy resin-based FRC. Both of them are produced by the technique of filament winding forming. By this method, continuous fiber filaments or cloth tapes are firstly impregnated with specific liquid resin and then wound onto a given mandrel to get the desired shape and wall thickness. After that, through high-temperature curing and demolding, semi-products can be obtained. Finished products of high precision can be availabe after CNC machining.

Phenolic resin-based FRC is a wear resistant material of single-layer structure. FRC1,FRC2,FRC3,FRC4 are typical phenolic resin-based products.They are often used as wear ring (guide ring, supporting ring) for pistons of hydraulic cylinders, or guide bush for pillars of hydraulic machinery. Epoxy resin-based FRC is a wear resistant material of two-layer structure . This category of material is commonly used as bushings or thrust washers in a variety of machinery or equipment. FRC5 is a typical epoxy resin-based product .

Phenolic resin based FRC

FRC1

Material composition: linear phenolic resin+cotton fiber fabric

FRC2

Material composition: soluble phenolic resin containing graphite+cotton fiber fabric

FRC3

Material composition: linear phenolic resin+polyester fiber fabric

FRC4

Material composition: soluble phenolic resin containing MoS2+carbon fiber fabric

Properties of FRC1/FRC2/FRC3/FRC4Note: more colors are available,depending upon the fillers.

Epoxy resin based FRCFRC5

Material structure and composition

Material structure and composition-lining layer

PTFE fiber filaments and polyester fiber filaments are continuously wound and encapsulated in high temperature solid lubricated-filled epoxy resin.

-backing layer

glass fiber filaments are continuously wound and encapsulated in high temperature epoxy resin.

Properties of FRC5Product features-Self-lubricating, maintenance-free.

-Good chemical resistance.

-High load carrying capacity.

-Low friction and high wear resistance.

-Excellent shock and misalignment resistance.

-Excellent contamination resistance.

Typical applicationshydraulic cylinders,engineering machinery,mining machinery, lifting equipment,etc.

In the electrolytic cell filled with electrolyte into the direct current, water molecules in the electrode electrochemical reaction, can be decomposed into hydrogen and oxygen, the whole process can achieve zero emissions. In the whole manufacturing process, the core equipment carrier is the electrolytic cell. Usually, the structure of the electrolytic cell is composed of three parts, namely, the tank body, the anode and the cathode. When direct current passes through the electrolytic cell, an oxidation reaction occurs at the interface between the anode and the solution, and a reduction reaction occurs at the interface between the cathode and the solution. At present, China's electrolytic water hydrogen production equipment is mostly used in photovoltaic, wind power, renewable energy hydrogen production is the main direction.

ORDER ONLINE

Filling in your phone and email information will help us to contact you in a timely manner and resolve your issue as soon as possible.

- DESCRIPTION

-

Product introduction

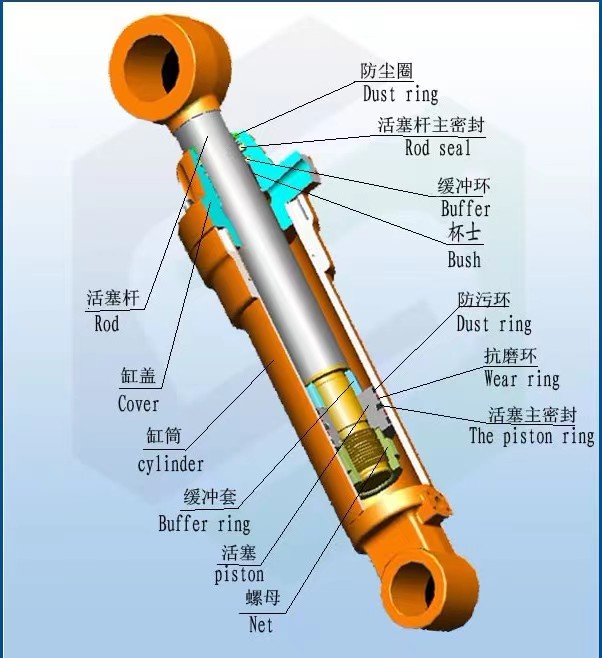

FRC is composed of thermosetting resin and high-strength fibers. The thermosetting resin provides strong support and dimensional stability for the composite. High-strength fibers serve as reinforcement material. FRC products are characterized by light weight,high load capacity, high wear resistance,very low friction, excellent corrosion resistance. They are particularly suitable for low speed, medium to high load applications.

FRC can be categorized into phenolic resin-based FRC and epoxy resin-based FRC. Both of them are produced by the technique of filament winding forming. By this method, continuous fiber filaments or cloth tapes are firstly impregnated with specific liquid resin and then wound onto a given mandrel to get the desired shape and wall thickness. After that, through high-temperature curing and demolding, semi-products can be obtained. Finished products of high precision can be availabe after CNC machining.

Phenolic resin-based FRC is a wear resistant material of single-layer structure. FRC1,FRC2,FRC3,FRC4 are typical phenolic resin-based products.They are often used as wear ring (guide ring, supporting ring) for pistons of hydraulic cylinders, or guide bush for pillars of hydraulic machinery. Epoxy resin-based FRC is a wear resistant material of two-layer structure . This category of material is commonly used as bushings or thrust washers in a variety of machinery or equipment. FRC5 is a typical epoxy resin-based product .

Phenolic resin based FRC

FRC1

Material composition: linear phenolic resin+cotton fiber fabric

FRC2

Material composition: soluble phenolic resin containing graphite+cotton fiber fabric

FRC3

Material composition: linear phenolic resin+polyester fiber fabric

FRC4

Material composition: soluble phenolic resin containing MoS2+carbon fiber fabric

Properties of FRC1/FRC2/FRC3/FRC4Note: more colors are available,depending upon the fillers.

Epoxy resin based FRCFRC5

Material structure and composition

Material structure and composition-lining layer

PTFE fiber filaments and polyester fiber filaments are continuously wound and encapsulated in high temperature solid lubricated-filled epoxy resin.

-backing layer

glass fiber filaments are continuously wound and encapsulated in high temperature epoxy resin.

Properties of FRC5Product features-Self-lubricating, maintenance-free.

-Good chemical resistance.

-High load carrying capacity.

-Low friction and high wear resistance.

-Excellent shock and misalignment resistance.

-Excellent contamination resistance.

Typical applicationshydraulic cylinders,engineering machinery,mining machinery, lifting equipment,etc.

In the electrolytic cell filled with electrolyte into the direct current, water molecules in the electrode electrochemical reaction, can be decomposed into hydrogen and oxygen, the whole process can achieve zero emissions. In the whole manufacturing process, the core equipment carrier is the electrolytic cell. Usually, the structure of the electrolytic cell is composed of three parts, namely, the tank body, the anode and the cathode. When direct current passes through the electrolytic cell, an oxidation reaction occurs at the interface between the anode and the solution, and a reduction reaction occurs at the interface between the cathode and the solution. At present, China's electrolytic water hydrogen production equipment is mostly used in photovoltaic, wind power, renewable energy hydrogen production is the main direction.